LITHOPROTECT® YELLOW LIGHT PRODUCTS

Requirements for suitable yellow films

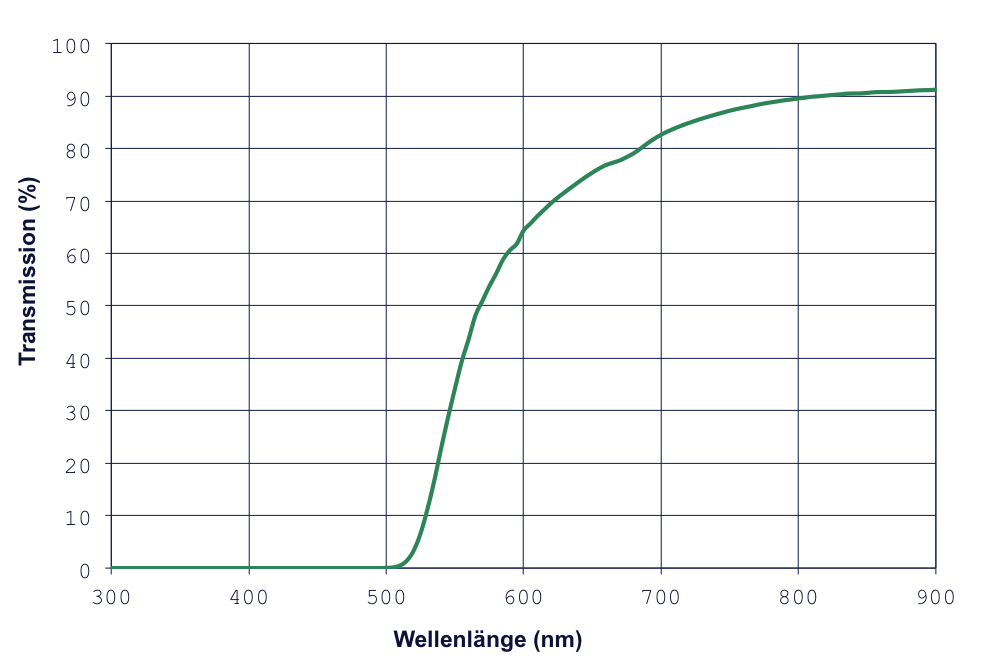

The spectral sensitivity of most photoresists is not only

in the near ultraviolet (wavelengths > 320 nm) spectral range,

but also extends into the visible range of the spectrum.

Even at 435 nm (g-line), most photoresists still absorb very

strongly and this absorption lies in the middle of the blue range of the spectrum

and falls off towards longer wavelengths without a sharp edge.

In order to

ensure that a coated substrate can be exposed to yellow light

for several hours without the resist layer being exposed unintentionally,

wavelengths < 500 nm must be blocked below the detection limit by appropriate optical filters (yellow film)

.

At the same time,

yellow films should be as transparent as possible

above a wavelength of 540 nm, i.e. in the range of the

sensitivity maximum of the human eye. With these conditions, a yellow space can be brightly illuminated with reasonable

energy expenditure without influencing the photoresist processing

.

This transmission spectrum is not to be understood as a specification, but as an exemplary measurement on a batch.

Lithoprotect® Properties

Lithoprotect® UV protection products have been specially developed for UV photosensitive applications and reliably block UV radiation below 520 nm. Lithoprotect® UV protection products

are made of yellow through-coloured cellulose triacetate. Due to the

through-colouring, reliable

UV protection below 520 nm can be guaranteed even for demanding applications. The UV blocking filter

is used in photolithography, printed circuit board and

microelectronics production, printing plate and photoresist production as well as

when handling photoresists and diazo films. Our films are even used in

pharmaceutical research, development and production.

The Lithoprotect® yellow film Y520

is waterproof and resistant to oils, greases, petrol and aliphatic

hydrocarbons. The yellow film is dissolved or swollen by chlorinated hydrocarbons,

ketones and aromatic solvents. This

can impair the optical properties. The UV protection film is

not resistant to concentrated acids and alkalis. The film is attacked in these

substances.

Lithoprotect® Areas of application

Lithoprotect® UV protection yellow film Y520 can be processed like paper. It can be applied to windows, privacy screens, room dividers, lamps and in front of openings using double-sided adhesive tape. For large window applications, we recommend our Lithoprotect® UV protection yellow film YSA520 self-adhesive. The Lithoprotect ® UV protection yellow film YSA520 self- adhesive can be applied easily and bubble-free to any smooth and solid surface using the mounting fluid DXMF301.

For filtering fluorescent tubes, durXtreme offers you special polycarbonate sleeves (Y520 T5 and Y520 T8) into which the Lithoprotect® UV blocking filter is incorporated, allowing you to produce UV-free light sources (yellow light) from normal fluorescent tubes at low cost.

We recommend the Lithoprotect® products for filtering short-wave radiation for the processing of photochemicals, which are divided into film (self-adhesive and non-self-adhesive) and sleeves for fluorescent tubes fitted with filter film.

The listed Lithoprotect® products are available from our partner company durXtreme GmbH.

Lithoprotect® Products

UV-protective yellow film

> Lithoprotect® UV-protective yellow film Y520> Lithoprotect® UV-protective yellow film YSA520 self-adhesive

Filter tubes

> Lithoprotect® UV protection filter tubes Y520 T5 for T5 lamps> Lithoprotect® UV protection filter tubes Y520 T8 for T8 lamps

Accessories

> Lithoprotect ® Seam tape YST520> Lithoprotect® Mounting fluid DXMF301

> Lithoprotect® Plastic squeegee DXRA100

If you are interested in Lithoprotect® yellow light products, have questions about their application or require technical information, please contact our partner durXtreme GmbH.

You can also order conveniently via the Lithoprotect® Online shop online shop.

durXtremeGmbH

Nicolaus-Otto-Str. 39

89079 Ulm

Germany

Web: www.lithoprotect.com

Mail: info@lithoprotect.com

Phone: +49 (0) 731 36080916

Fax: +49 (0) 731 36080917