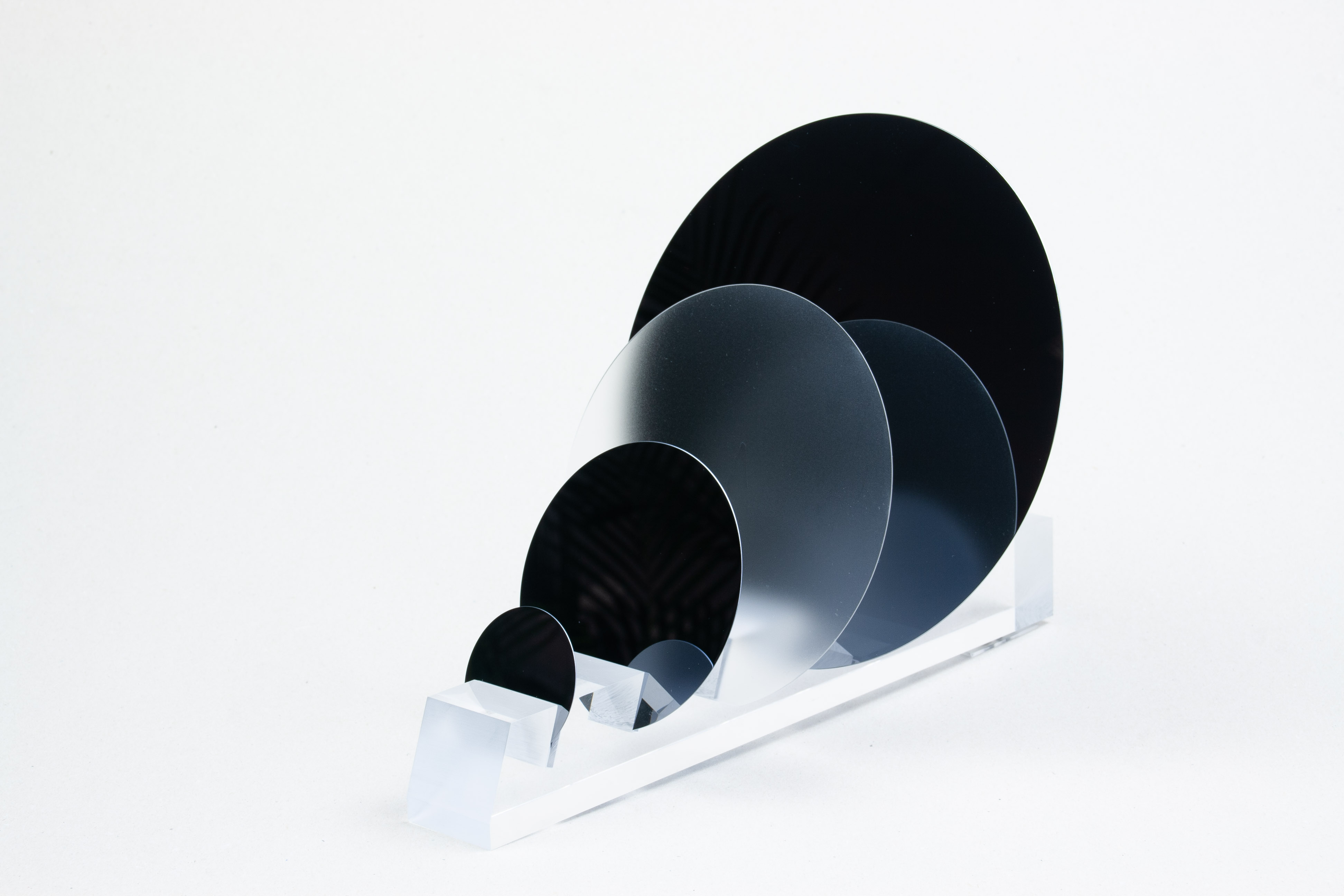

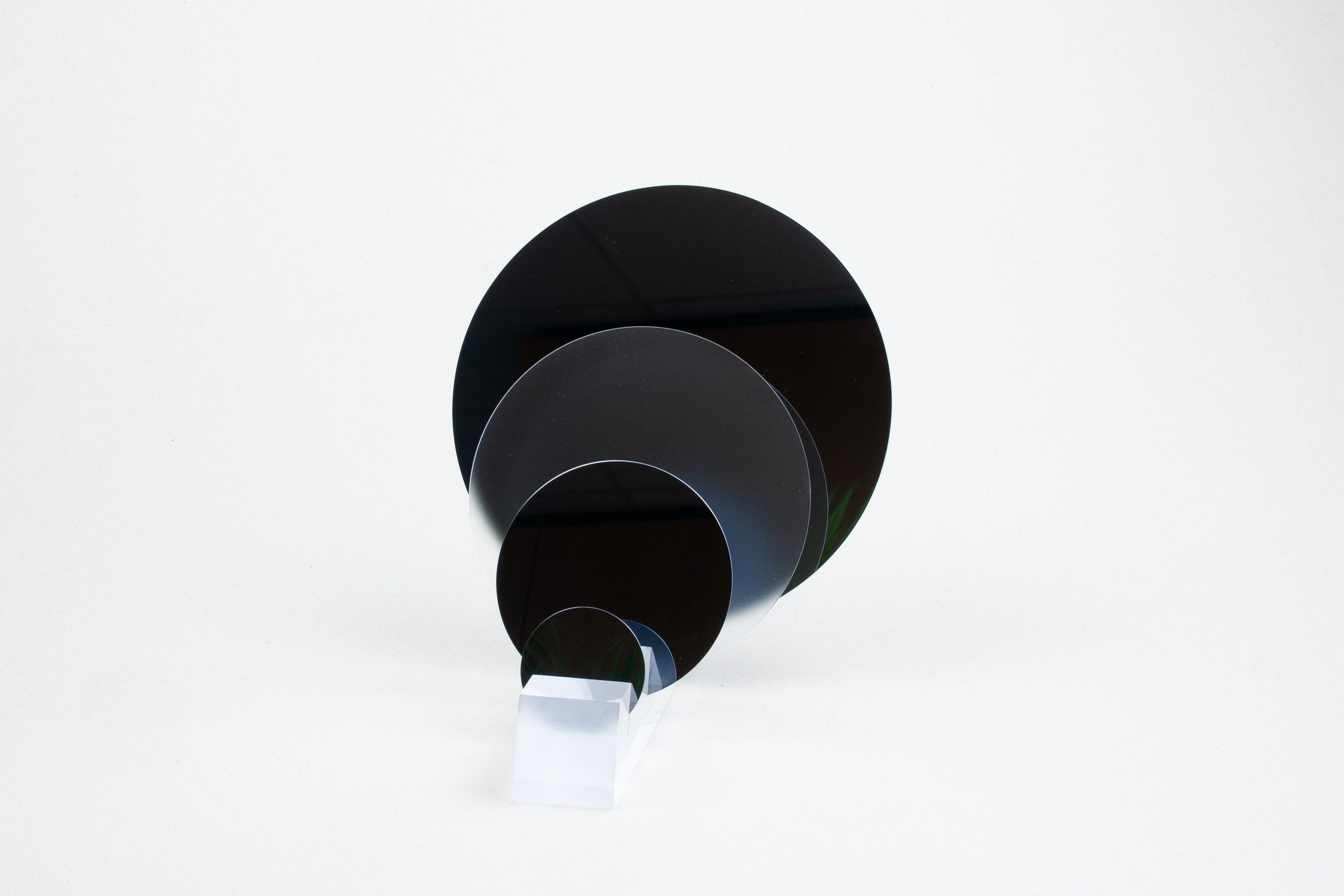

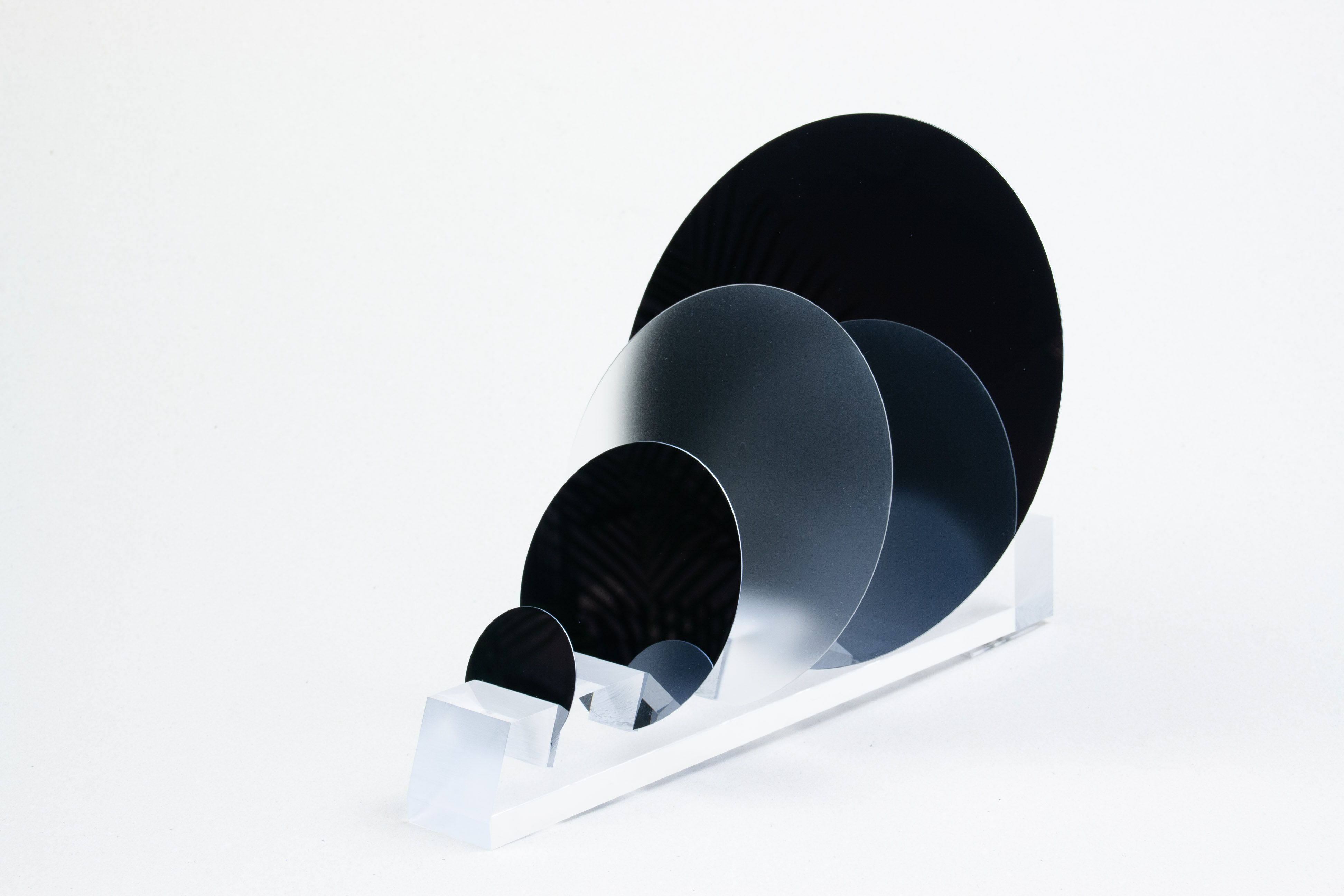

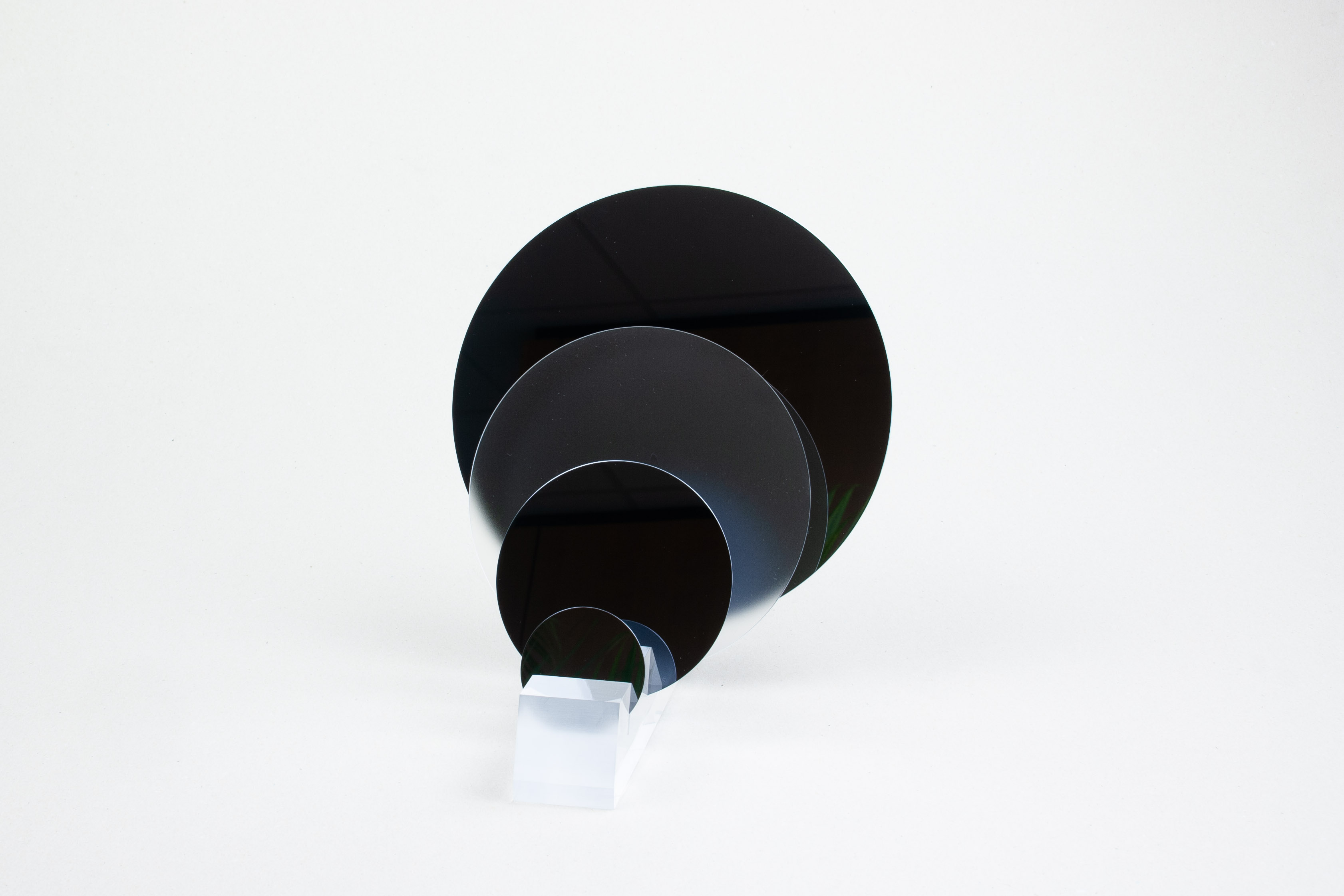

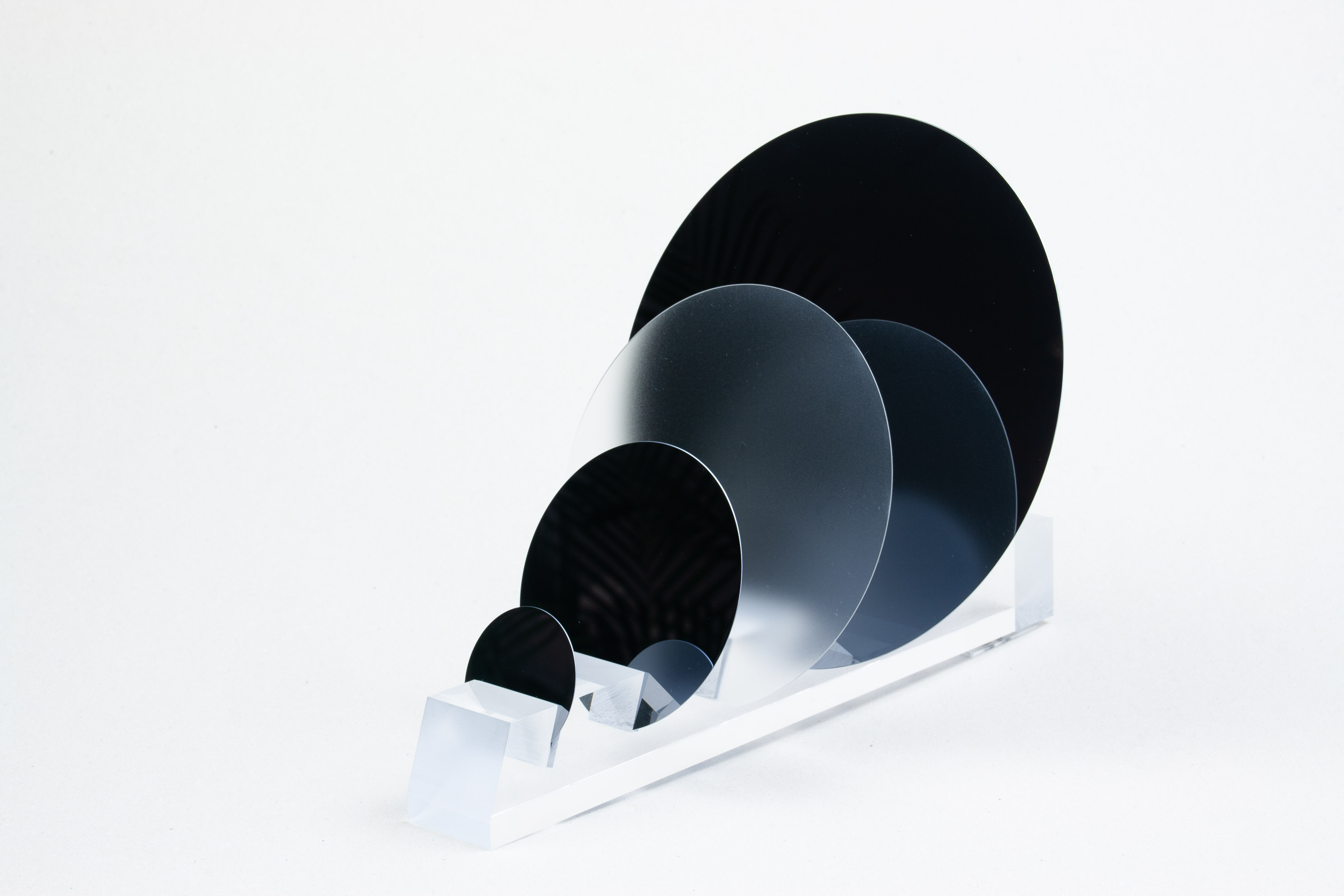

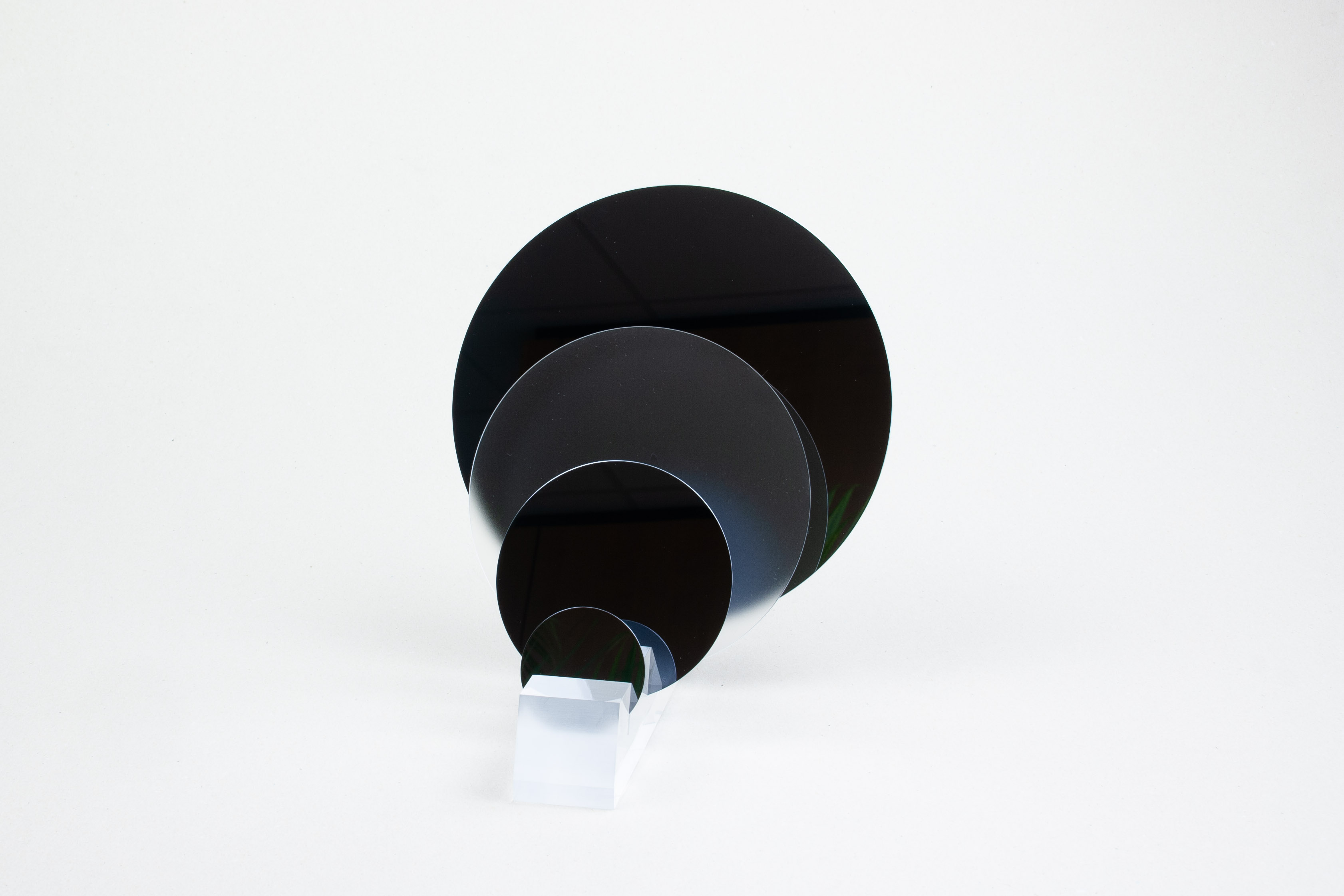

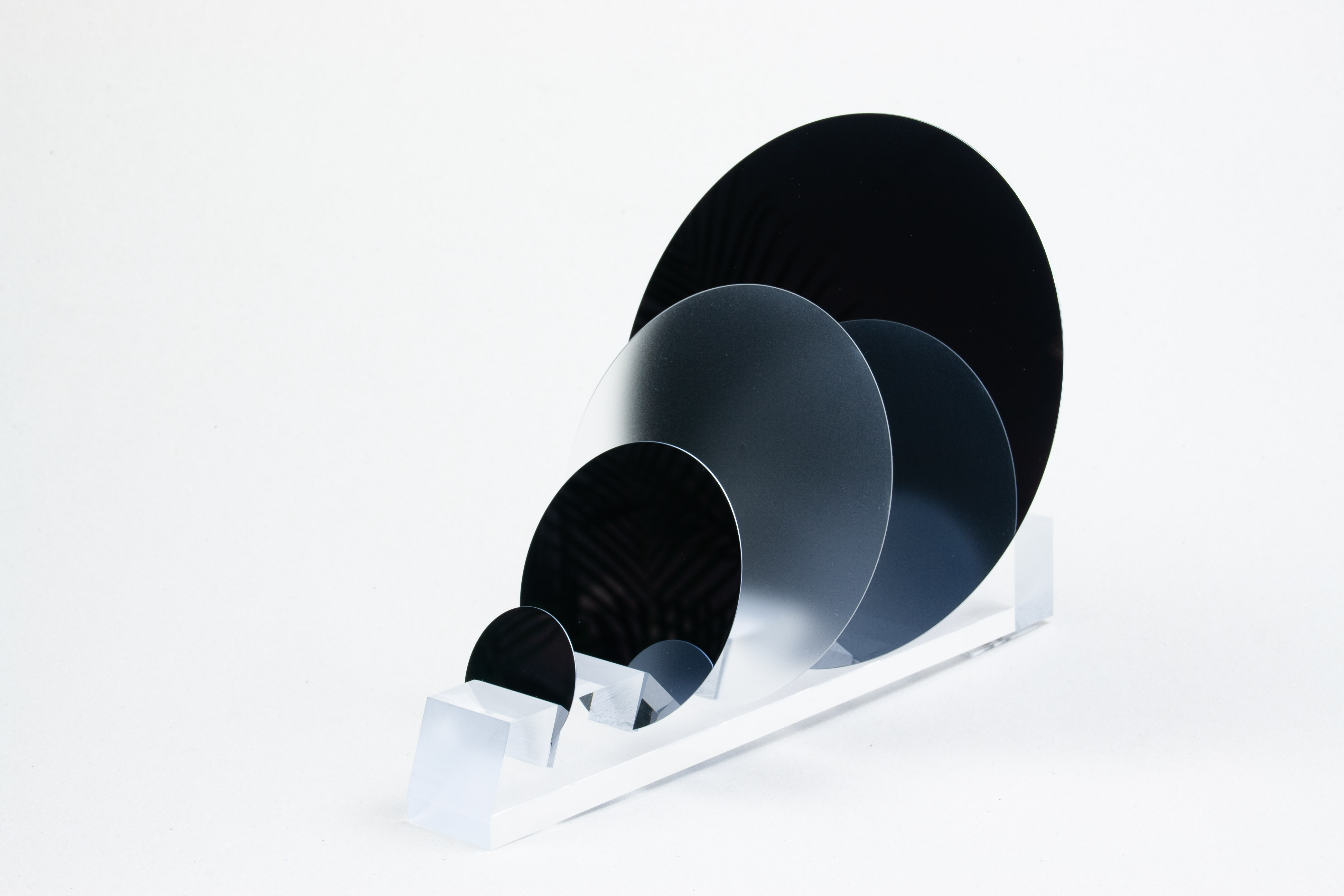

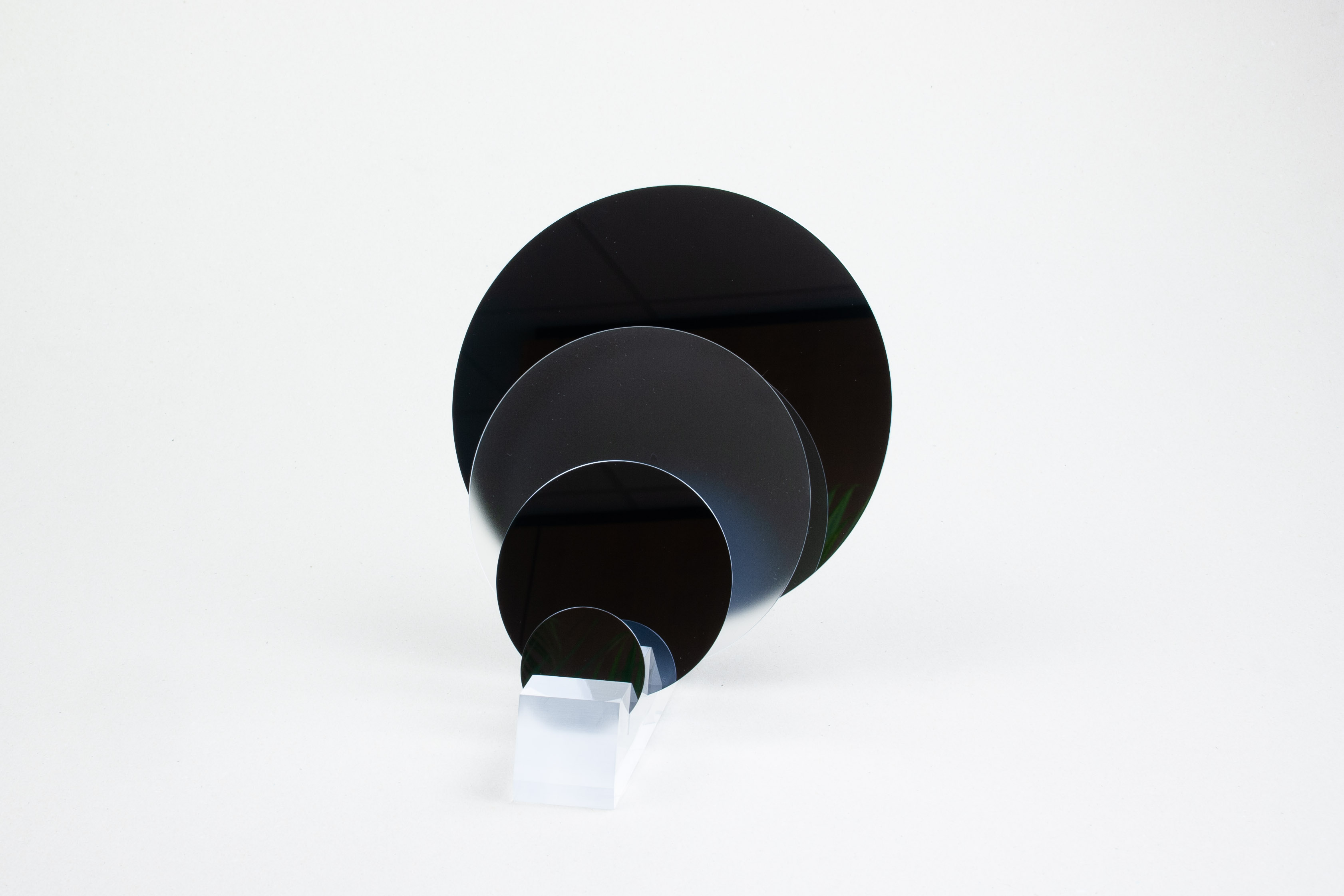

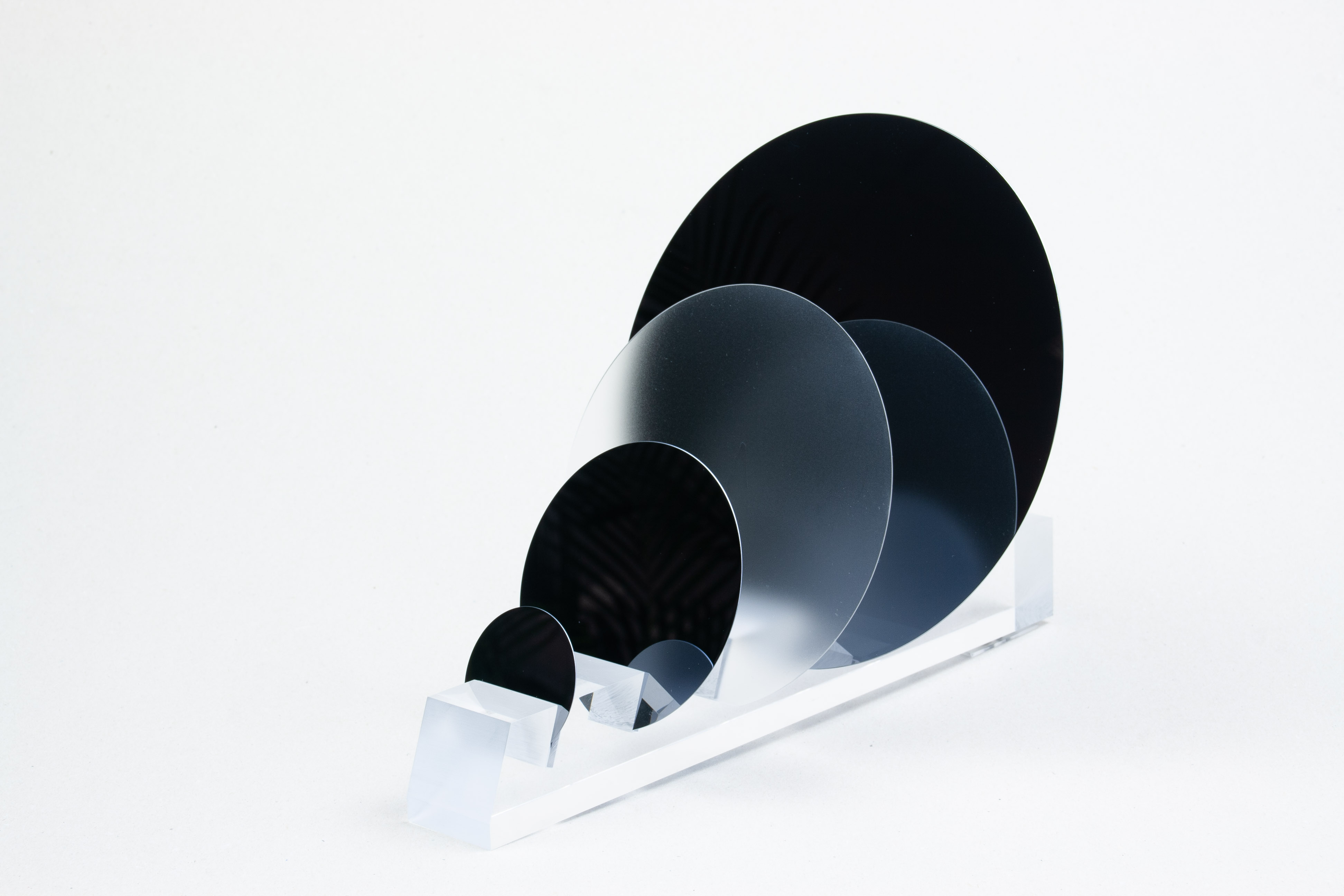

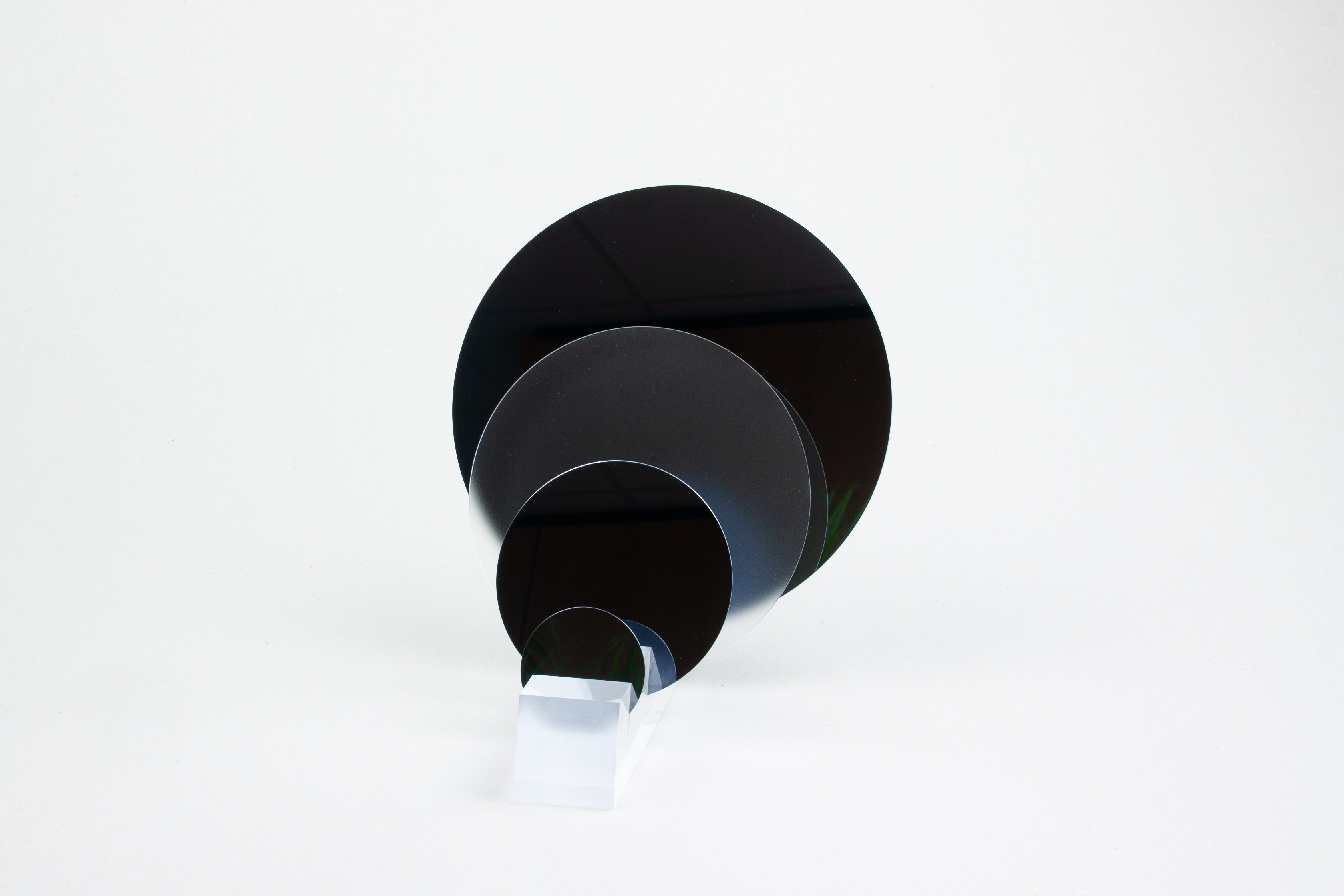

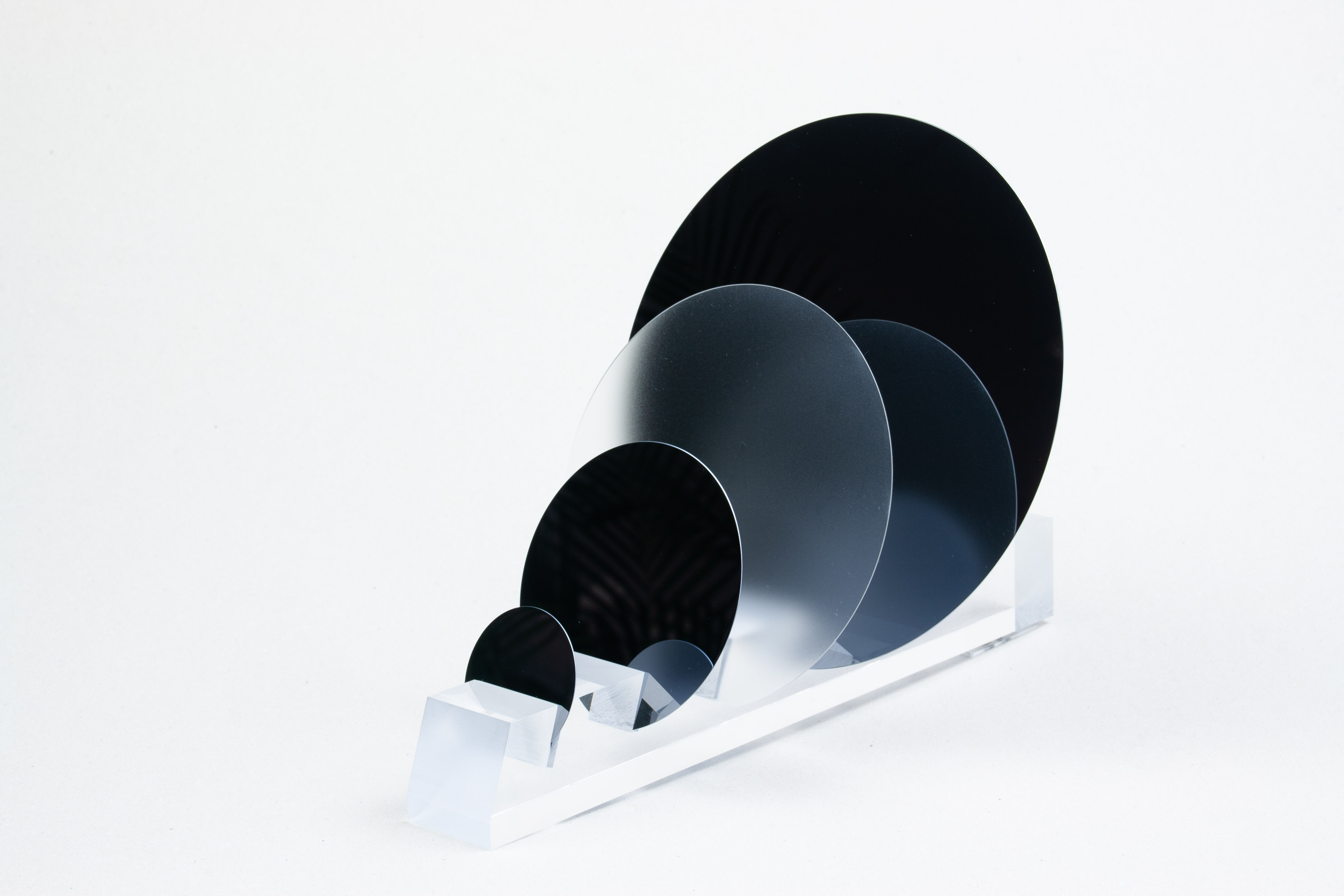

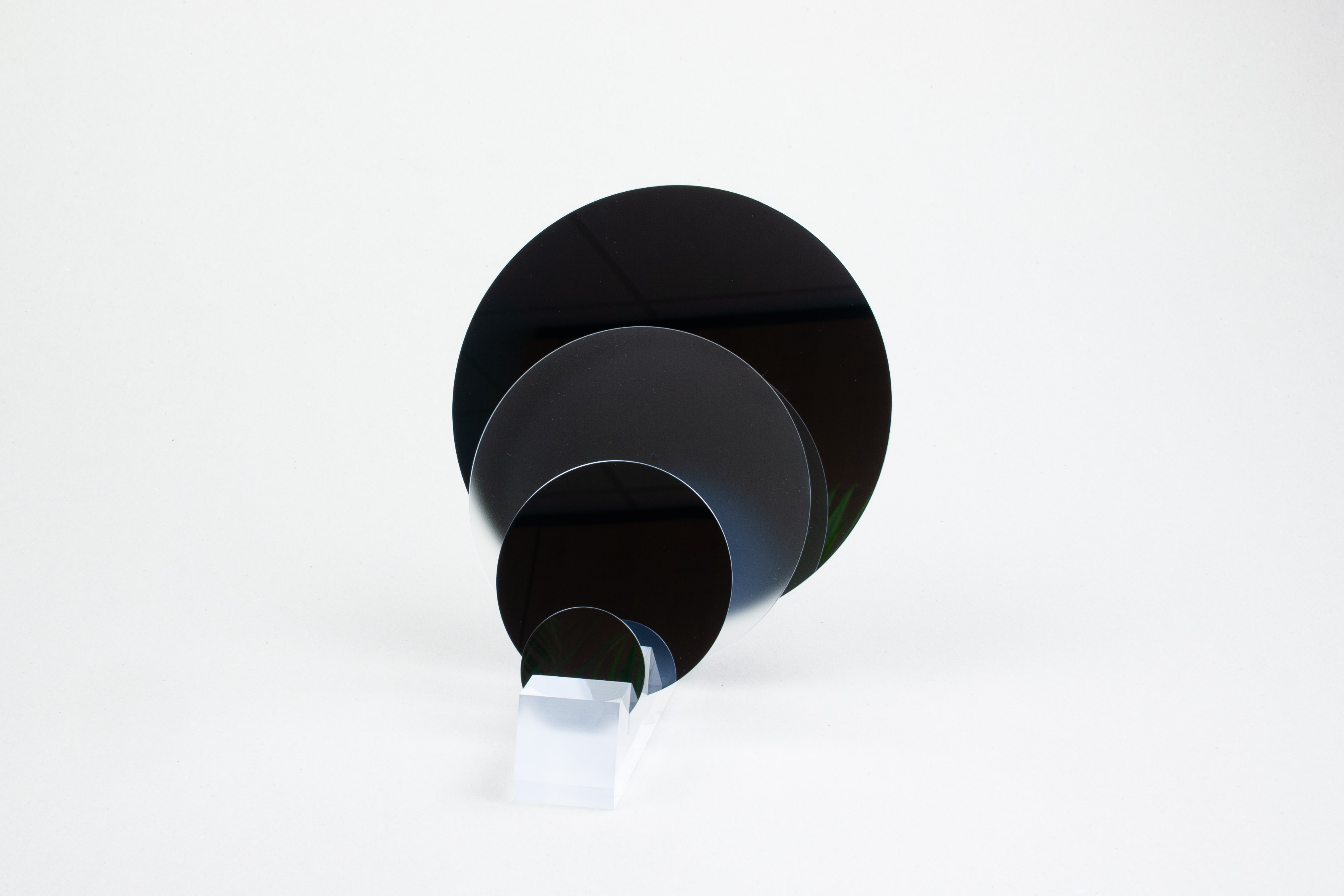

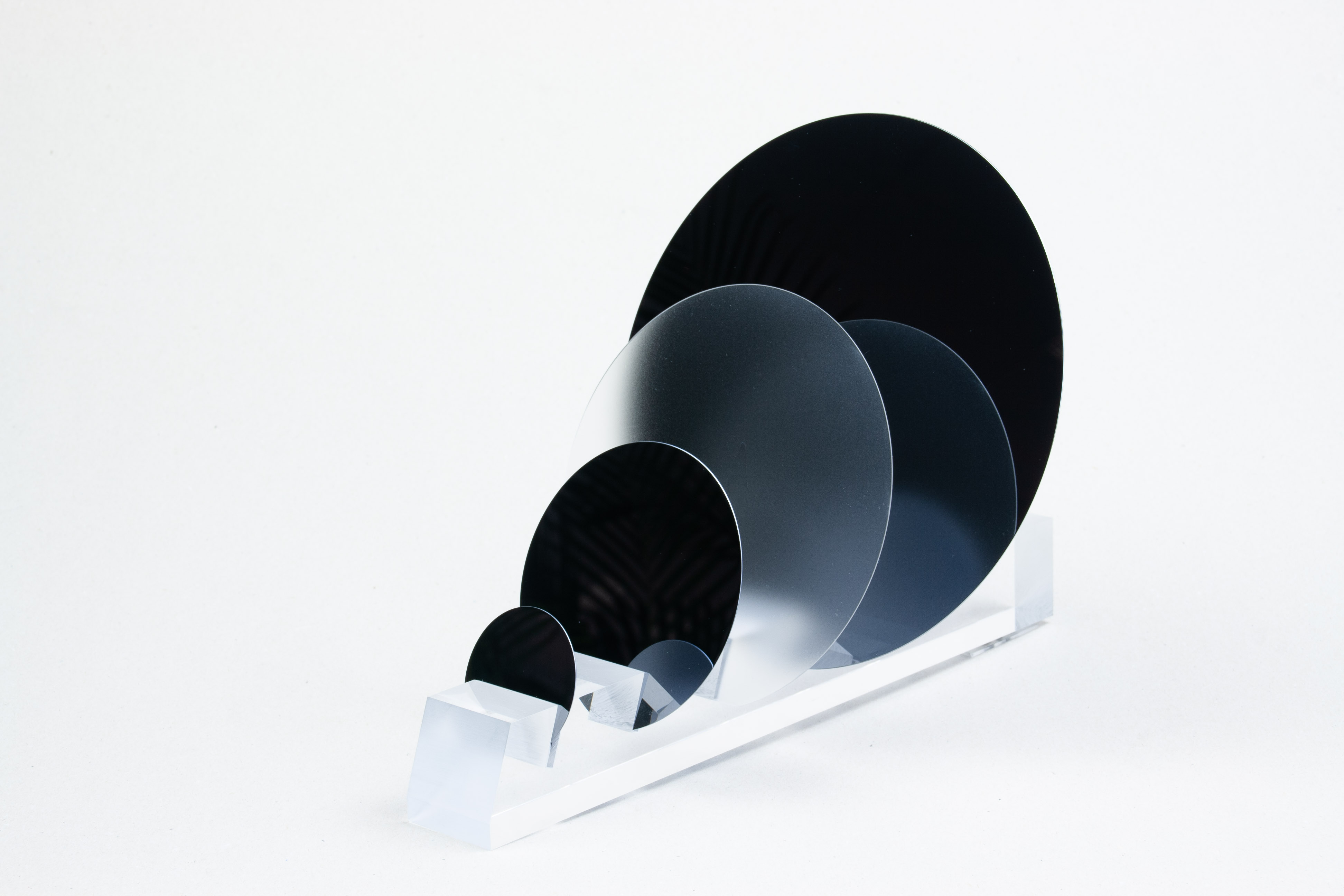

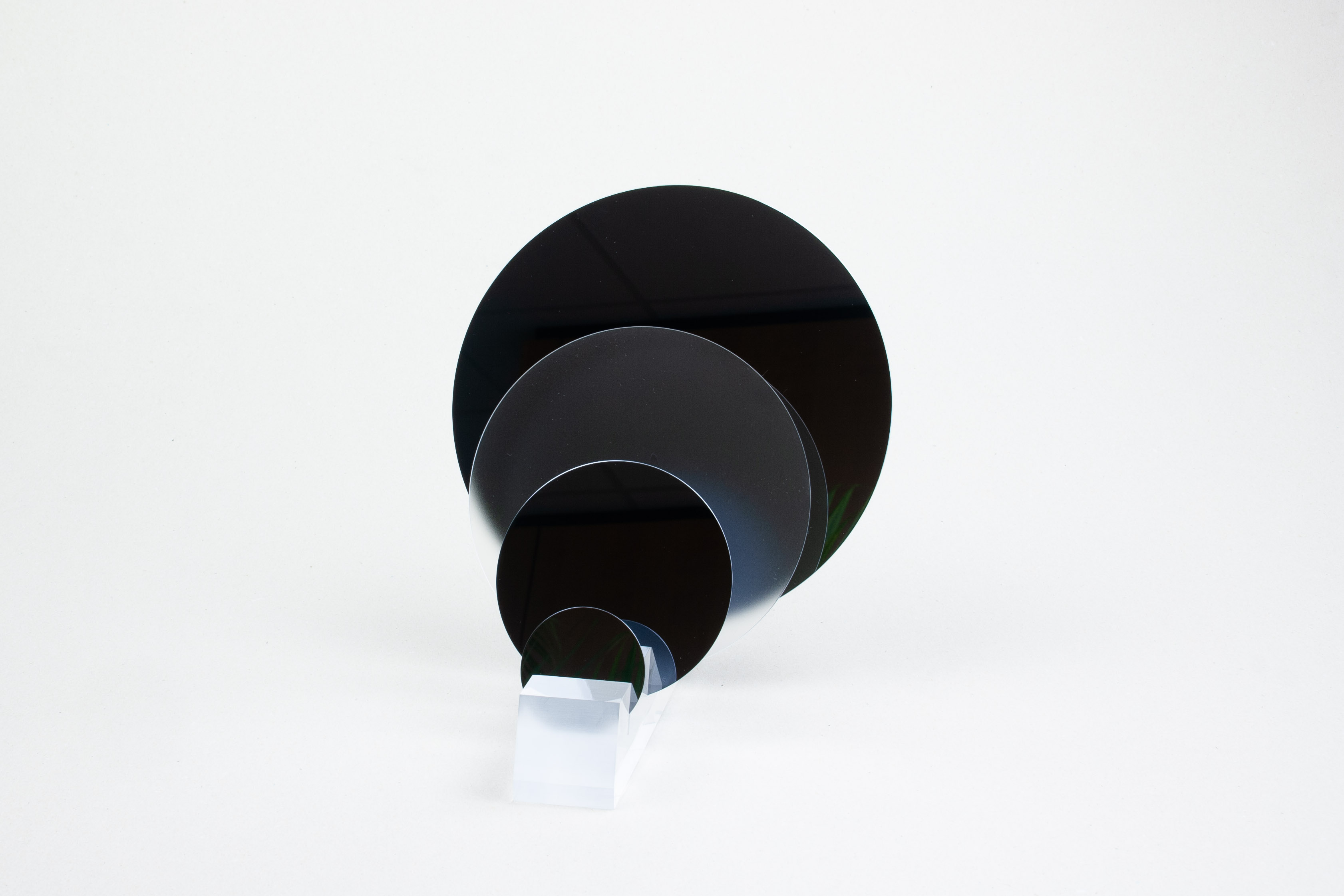

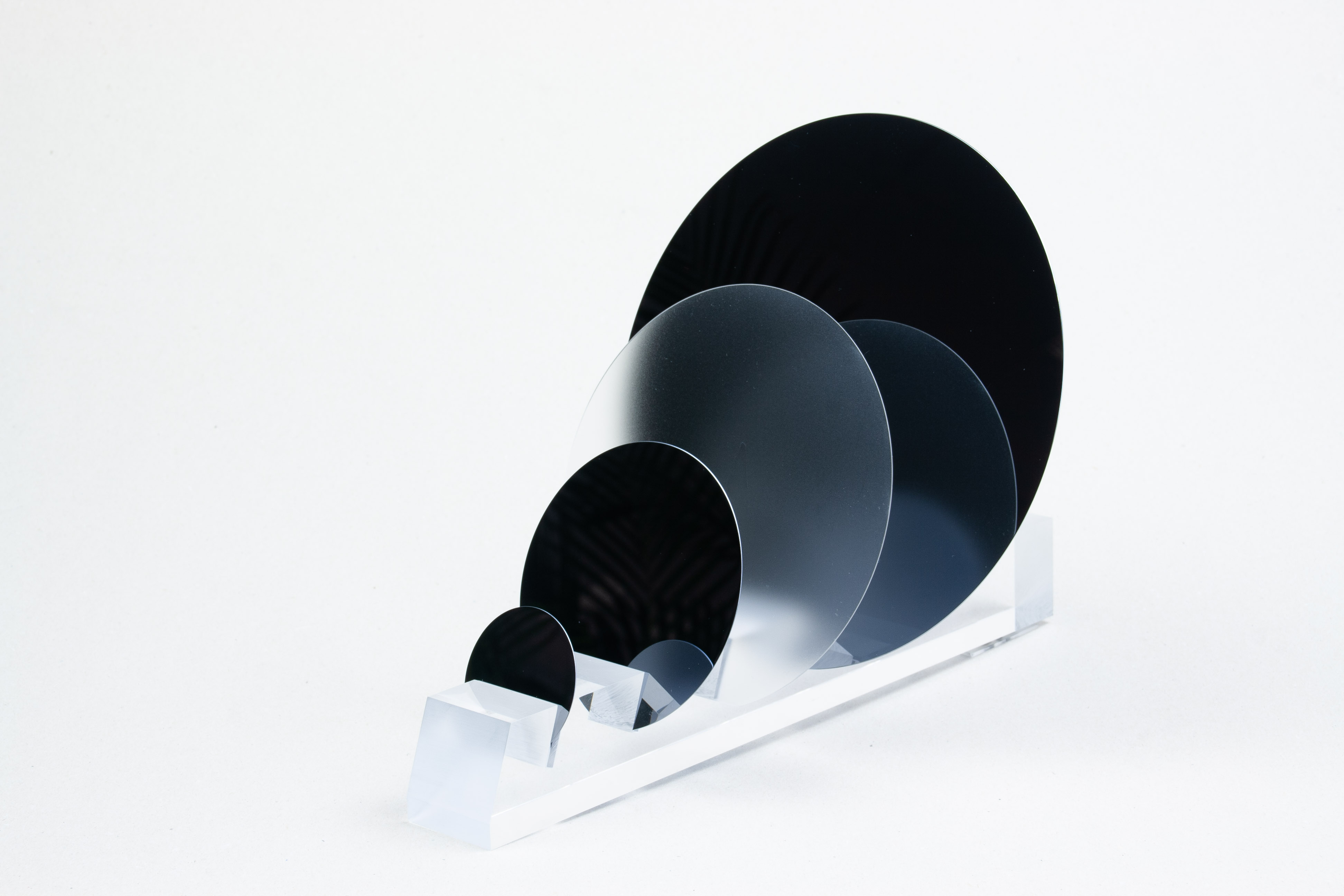

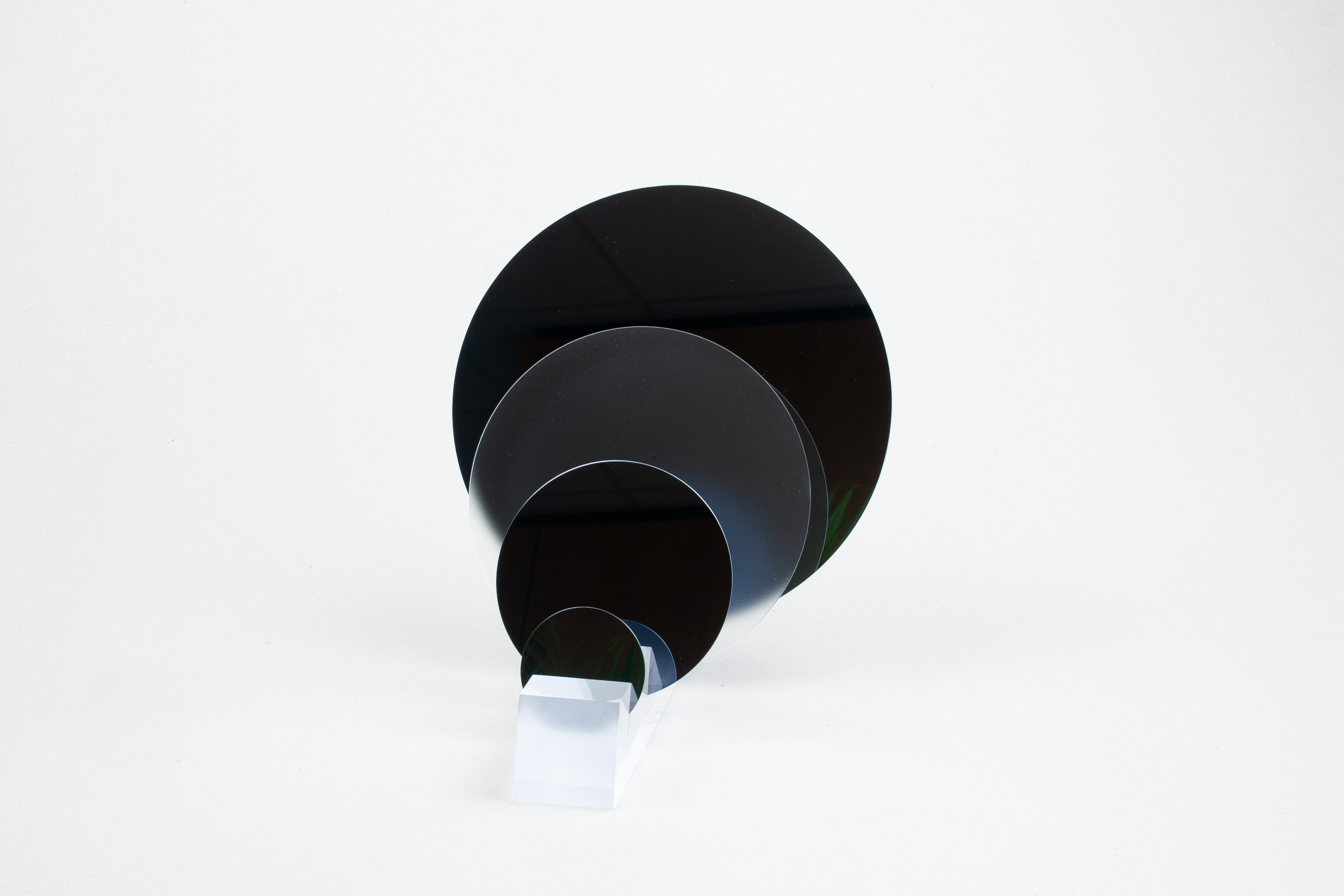

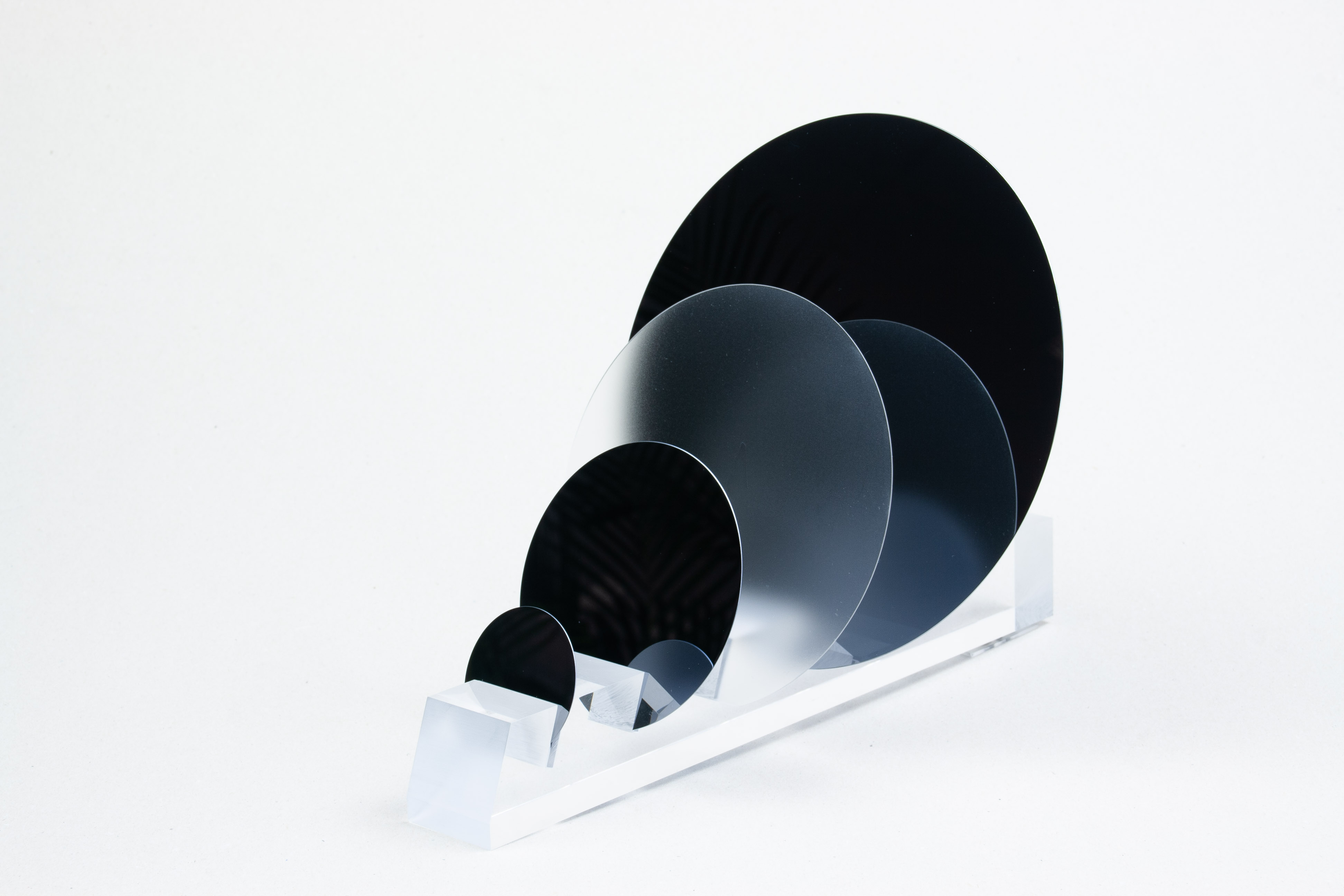

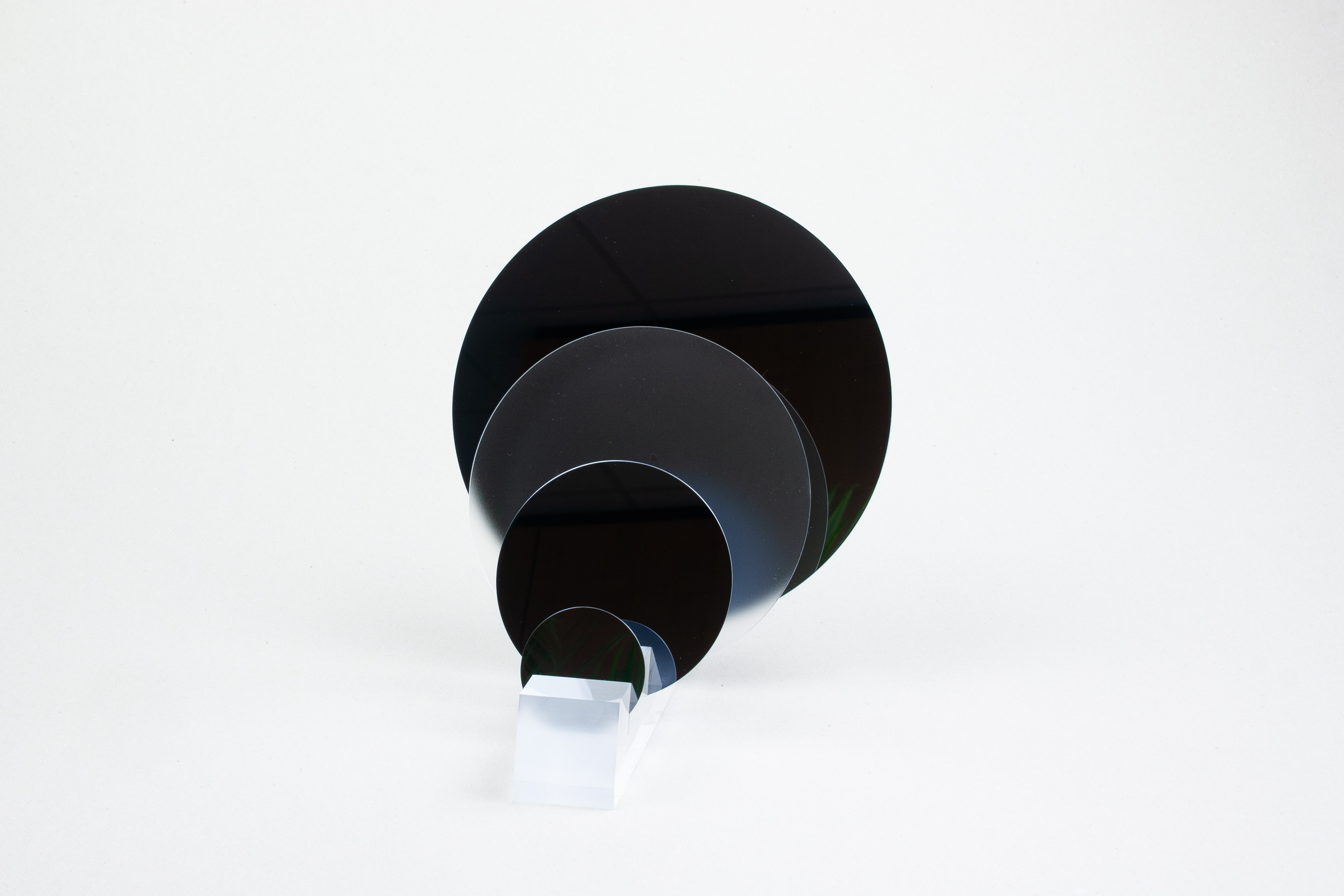

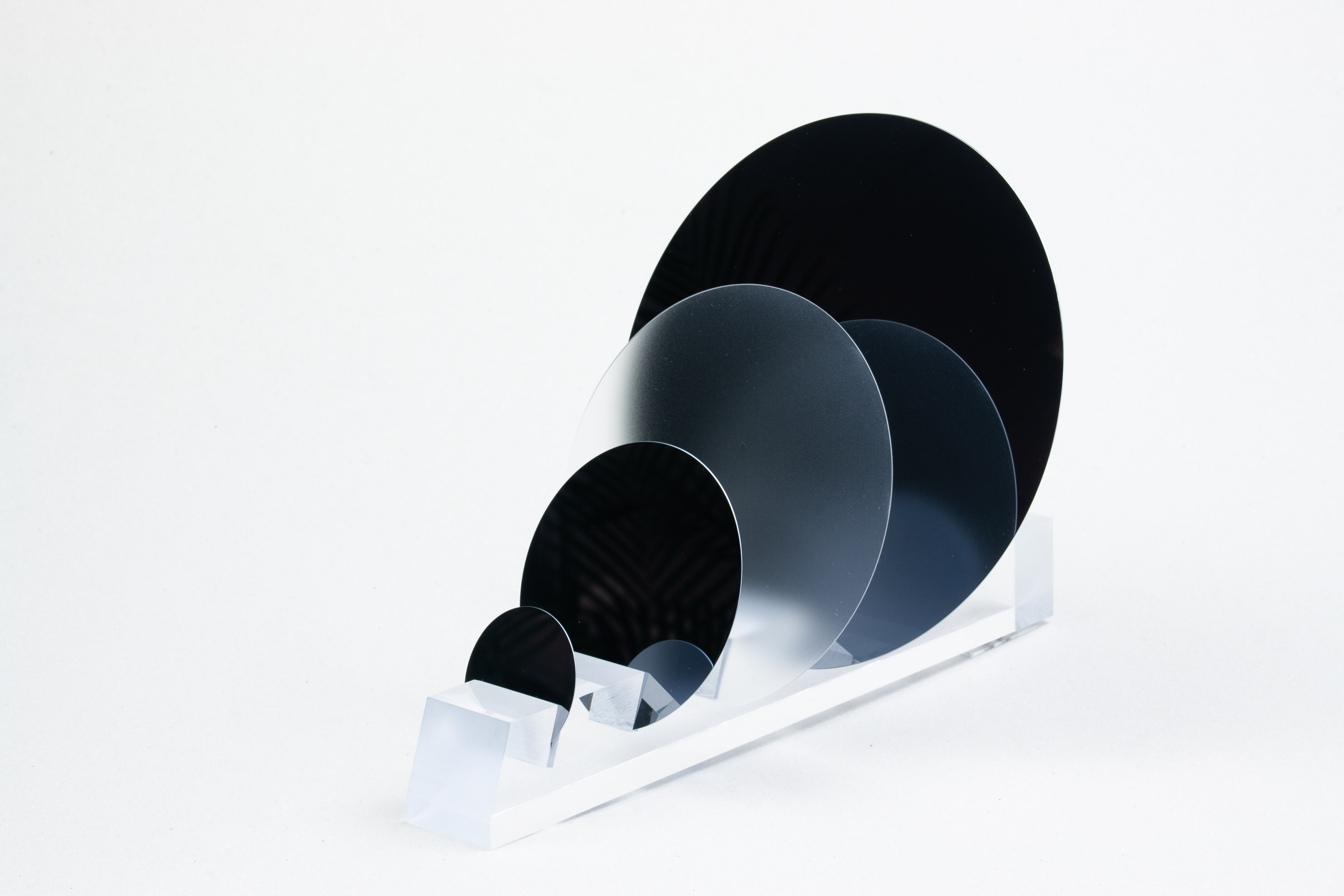

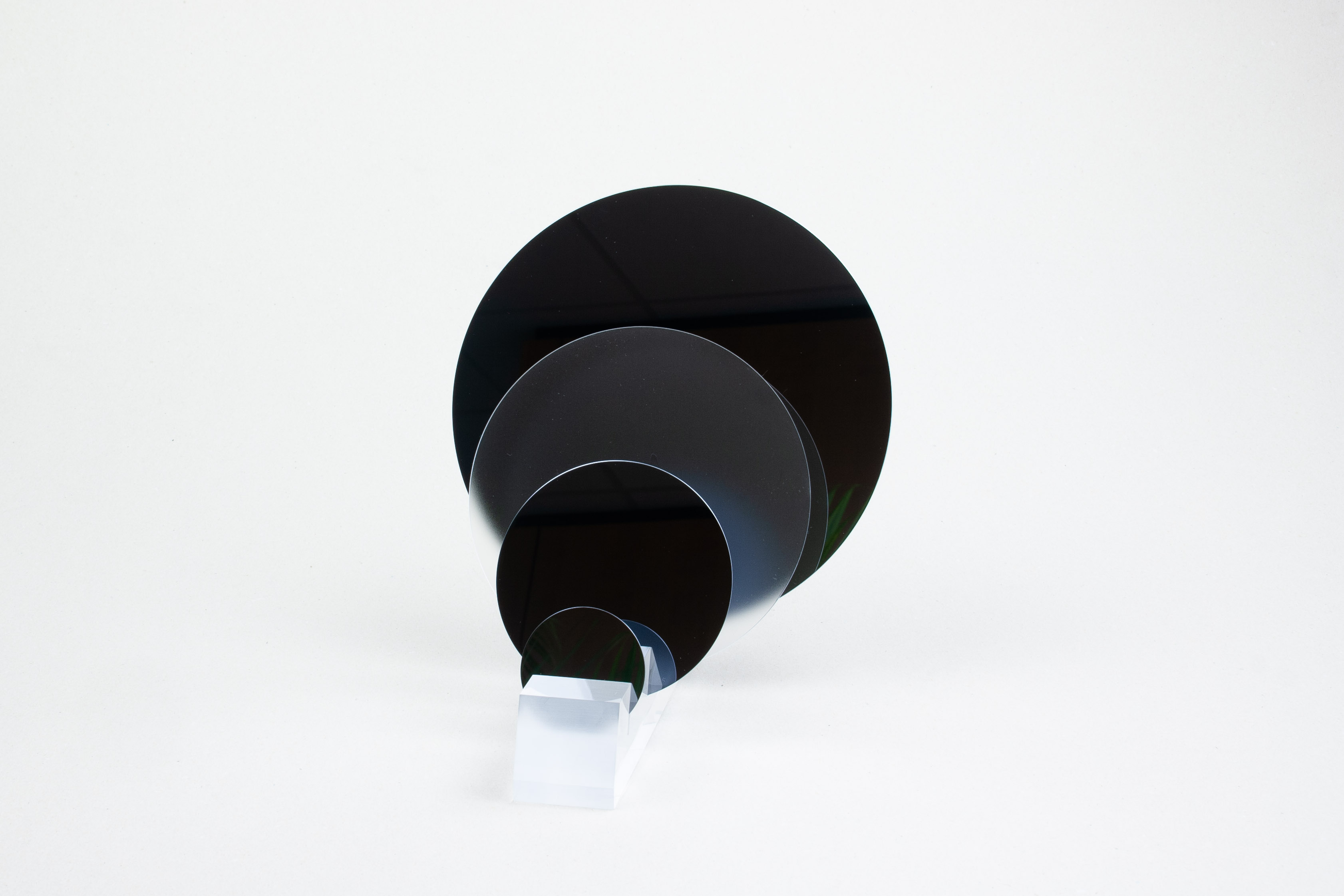

QUARZ WAFER

Diameter and shape

We can offer single crystal quartz wafers with 2, 3 and 4 inch diameter . Unless otherwise stated, "inch" in this context means 25.0 mm for 4 inch and larger wafers, and 25.4 mm for 1 and 2 inch wafers. In addition to round wafers, wafers separated into rectangular pieces are also possible. Due to the high fixed costs of the separation process, it usually only makes economic sense to order quantities that correspond to the separation of approx. 10 initial wafers. However, we also occasionally keep smaller quantities of frequently requested separated wafers in stock.

Surface

Quartz wafers are usually polished on both sides, for certain applications also on one side. The roughness is usually specified as "< 1.5 nm" or "< 1.0 nm". As with Si wafers, even the finest polishing marks define the surface quality of the polished side(s), which is defined by the size S/D (usually 40/20).

Production of quartz wafers

The starting material

The starting material for growing quartz single crystals are naturally occurring, high-purity quartz crystals (so-called "lascas"), which can be used in cm-sized fragments without further purification for the crystal growing process described in the following section.

Crystal growing

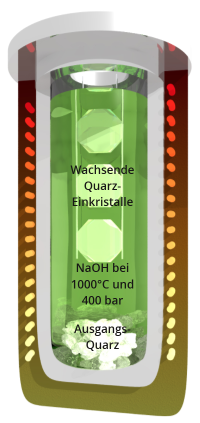

Single crystals of quartz are produced synthetically according to the hydrothermal principle (Fig. below). In this process, quartz crystallises at a temperature of around 400°C and a pressure of approx. 1000 - 1500 bar from a saturated NaOH solution on quartz seed crystals that are at a slightly lower temperature than the quartz pieces, which are continuously dissolved as starting material. Crystal growth can take hours to days, with the resulting single crystals weighing up to several kg.

Growing quartz single crystals according to the hydrothermal principle.

Further Information:

> Application areas and compatibilities

> Image Reversal Resist Processing

Filter products