SOLVENTS

In addition to etching processes, the

solubilities of substances often play a decisive role in microstructuring. This does not

only apply to the structuring of organic layers, but to all

wet chemical etching processes: In addition to chemical removal, the

etched substances must be dissolved in the etching medium.

> Solvents: theory and application

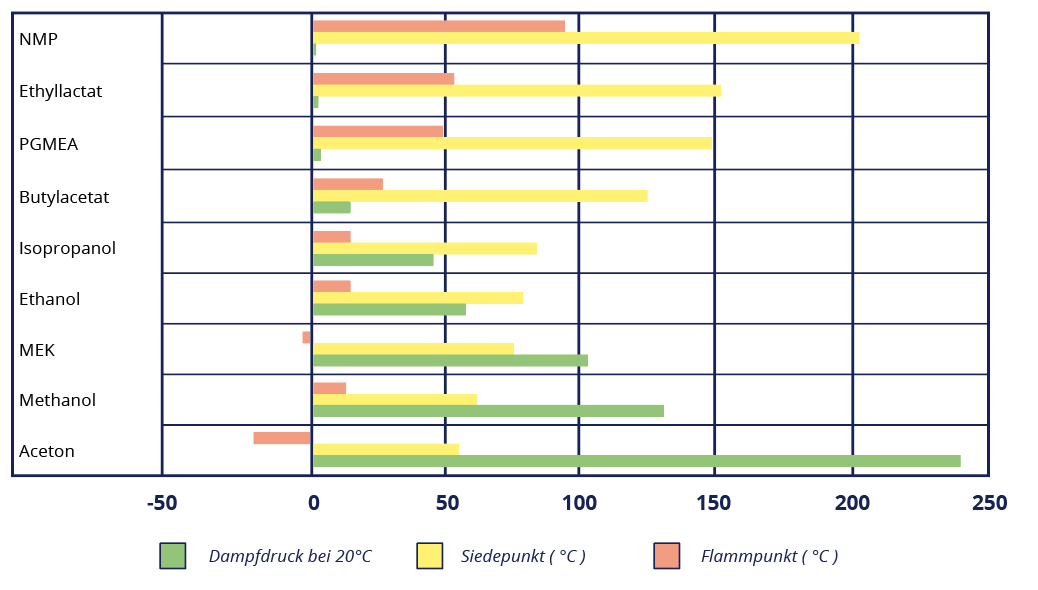

Overview of the physical properties of the solvents.

Filter

–

Acetone MC - 2.50 l - ULSI - EUD/EVE!

MACU1025

Manufacturer:

MicroChemicals GmbH

|

Bottle size:

2.50 l

|

Purity:

ULSI

Acetone

CH3COCH3

General Information

Acetone removes organic impurities from substrates and is well suited for greasy/oily contaminations. However, its large vapour pressure causes rapid drying together with a resorption of the contaminants on the substrate. Therefore an immediately subse¬quent rinsing step is recommended with a higher boiling solvent such as isopropanol.

Acetone is not well-suited as lift-off medium due to the high fire danger when heated and the trend of particles to be lifted to resorb onto the substrate.

Product Properties

Density: 0.79 g/cm^3

Melting point: 95°C

Boiling point: 56°C

Flash point: < -18°C

Vapour pressure @ 20°C: 244 hPa

Acetone Molecule

Further Information

MSDS:

Safety Data Sheet Acetone english (TECHNIC France)

Sicherheitsdatenblatt Aceton german (TECHNIC France)

Safety Data Sheet Acetone english (MicroChemicals GmbH)

Sicherheitsdatenblatt Aceton german (MicroChemicals GmbH)

Specs:

Specs Acetone ULSI (TECHNIC France)

Specs Acetone VLSI (TECHNIC France)

Specs Acetone ULSI (MicroChemicals GmbH)

Application Notes:

Solvents english

Lösemittel german

AZ EBR 70/30 - 1.00 l

10703021

Bottle size:

1.00 l

AZ® EBR Solvent 70/30

1-methoxy-2-propyl-acetate

General Information

AZ® EBR Solvent 70/30 is the main solvent/thinner of almost all AZ® and TI photoresists due to its low vapour pressure and its suppression of particle formation in the (further diluted) resist. Additionally, PGMEA is often used for edge bead removal, since its low vapour pressure prevents further thinning of the coated resist film.

Product Properties

Density: 0.97 g/cm3

Melting point: -66°C

Boiling point: 125°C

Flash point: 45°C

Vapour pressure @ 20°C: 5 hPa

PGMEA Molecule

Further Information

MSDS:

Safety Data Sheet AZ® EBR Solvent 70/30 english

Sicherheitsdatenblatt AZ® EBR Solvent 70/30 german

TDS:

Technical Data Sheet AZ® EBR Solvent 70/30 english

Information AZ® EBR Solvent 70/30 english

AZ EBR Solvent - 5.00 l

1000002

Bottle size:

5.00 l

AZ® EBR Solvent

1-methoxy-2-propyl-acetate

General Information

AZ® EBR Solvent is the main solvent/thinner of almost all AZ® and TI photoresists due to its low vapour pressure and its suppression of particle formation in the (further diluted) resist. Additionally, PGMEA is often used for edge bead removal, since its low vapour pressure prevents further thinning of the coated resist film.

Product Properties

Density: 0.97 g/cm3

Melting point: -66°C

Boiling point: 125°C

Flash point: 45°C

Vapour pressure @ 20°C: 5 hPa

PGMEA Molecule

Further Information

MSDS:

Safety Data Sheet AZ® EBR Solvent english

Sicherheitsdatenblatt AZ® EBR Solvent german

TDS:

Technical Data Sheet AZ® EBR Solvent english

Cyclopentanon - 2.50 l - ULSI

TCYU1025

Cyclopentanone

C5H8O

General Information

Cyclopentanone is often used in conjunction with epoxy-based resist formulations, as well as an organic developer for cross-linking photoresists such as e-beam resists.

Product Properties

Density: 0.88 g/cm3

Melting point: -77°C

Boiling point: 127°C

Flash point: 27°C

Vapour pressure @ 20°C: 10.7 hPa

Cyclopentanone Molecule

Further Information

MSDS:

Safety Data Sheet Cyclopentanon (ULSI) english

Sicherheitsdatenblatt Cyclopentanon (ULSI) german

Specs:

Specs Cyclopentanon (ULSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

DMSO - 2.50 l - ULSI

MDMU1025

DMSO

Dimethyl Sulfoxide

General Information

Due to its low vapour pressure and its water solubility, DMSO is an excellent stripper for resists respectively Lift-off media and is a non-toxic substitute for the NMP, which has been classified as toxic since a while. The optional addition of Cyclopentanone or MEK increases the performance of the stripper for certain applications and significantly lowers the melting point of pure DMSO.

NOTE:

The solvent DMSO (dimethyl sulfoxide) has a melting point just below room temperature, so it can possi¬bly freeze in storage in cooler rooms. Thawing may require several days, but afterwards the product can still be used as it is.

For more details please download the info letter.

Product Properties

Density: 1.1 g/cm3

Melting point: 18°C

Boiling point: 189°C

Flash point: 87°C

Vapour pressure @ 20°C: 0.56 hPa

DMSO Molecule

Further Information

MSDS:

Safety Data Sheet DMSO (ULSI) english

Sicherheitsdatenblatt DMSO (ULSI) german

Specs:

Specs DMSO (ULSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Photoresist Removal english

Fotolack entfernen german

Further Information about Processing

Isopropyl Alcohol MC - 2.50 l - ULSI

MIPU1025

Manufacturer:

MicroChemicals GmbH

|

Bottle size:

2.50 l

|

Purity:

ULSI

Isopropyl Alcohol

IPA, 2-propanol

General Information

Isopropyl alcohol is well-suited for rinsing contaminated acetone as well as removing particles from surfaces. Therefore, this solvent is often used in the second substrate cleaning step after acetone. Additionally, Isopropyl alcohol is used as additive for anisotropic Si-etching.

Product Properties

Density: 0.78 g/cm3

Melting point: - 88°C

Boiling point: 82°C

Flash point: 13°C

Vapour pressure @ 20°C: 43 hPa

Isopropyl alcohol Molecule*

Further Information

MSDS:

Safety Data Sheet Isopropyl Alcohol (ULSI) english

Sicherheitsdatenblatt Isopropyl Alcohol (ULSI) german

Safety Data Sheet Isopropyl Alcohol (VLSI) english

Sicherheitsdatenblatt Isopropyl Alcohol (VLSI) german

Specs:

Specs Isopropyl Alcohol (ULSI)

Specs Isopropyl Alcohol (VLSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

MC Spray Thinner MEK - 1.00 l

1SPTHM001

Bottle size:

1.00 l

MC Spray Thinner MEK

Solvent for Spray Coating

General Information

Spray Thinner MEK is a solvent for the production of a spray coating formulation. As the name suggests, this thinner is based on a formulation of MEK and various surfactants, which help to achieve an optimal spray coating result.

Spray coating formulations are often made from three components - the low-boiling Spray Thinner MEK, the high-boiling Spray Thinner PGMEA and the corresponding resist. Depending on the mixing ratio and the wanted result, the proportions of the substances must be adjusted.

A high proportion of PGMEA (low vapor pressure) creates very smooth layers with moderate edge coverage, while a formulation with a high MEK content (high vapor pressure) creates very good edge coverage but comparatively rough layers.

The optimal compromise of the solvent mixture is often a mixing ratio MEK: PGMEA of 1:3 to 3:1. Depending on the viscosity, required by the spray coating tool used, this solvent mixture is added to the resist in a ratio of 1:3 to 1:10. So one part resist to 3 parts solvent mixture up to one part resist to 10 parts solvent mixture.

Further Information

MSDS:

Safety Data Sheet MC Spray Thinner MEK english

Sicherheitsdatenblatt MC Spray Thinner MEK german

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

MC Spray Thinner PGMEA - 1.00 l

1SPTHP001

Bottle size:

1.00 l

MC Spray Thinner PGMEA

Solvent for Spray Coating

General Information

Spray Thinner PGMEA is a solvent for the production of a spray coating formulation. As the name suggests, this thinner is based on a formulation of PGMEA and various surfactants, which help to achieve an optimal spray coating result.

Spray coating formulations are often made from three components - the high-boiling Spray Thinner PGMEA, the low-boiling MEK Spray Thinner, and the corresponding resist. Depending on the mixing ratio and the wanted result, the proportions of the substances must be adjusted.

A high proportion of PGMEA (low vapour pressure) creates very smooth layers with moderate edge coverage, while a formulation with a high MEK content (high vapour pressure) creates very good edge coverage but comparatively rough layers.

The optimal compromise of the solvent mixture is often a mixing ratio MEK: PGMEA of 1:3 to 3:1. Depending on the viscosity, required by the spray coating tool used, this solvent mixture is added to the resist in a ratio of 1:3 to 1:10. So one part resist to 3 parts solvent mixture up to one part resist to 10 parts solvent mixture.

Further Information

MSDS:

Safety Data Sheet MC Spray Thinner PGMEA english

Sicherheitsdatenblatt MC Spray Thinner PGMEA german

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

MEK - 2.50 l - ULSI - EVE/EUD!

MMEU1025

MEK

Methyl Ethyl Ketone

General Information

MEK (methyl ethyl ketone) with its low boiling point can be used as MicroChemicals additional thinner for spray coating resists, which require a fast resist film drying on the substrate.

Product Properties

Density: 0.81 g/cm3

Melting point: -86°C

Boiling point: 80°C

Flash point: -4°C

Vapour pressure @ 20°C: 105 hPa

MEK Molecule

Further Information

MSDS:

Safety Data Sheet MEK (ULSI) english

Sicherheitsdatenblatt MEK (ULSI) german

Specs:

Specs MEK (ULSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

Methanol - 2.50 l - VLSI - EVE/EUD!

TMLU1025

Methanol

Methylalcohol

General Information

Methanol can be used for improved substrate cleaning due to its good dissolving power for contaminated acetone in a three-stage cleaning process (acetone à methanol à isopropyl alcohol). Due to its toxicity, its application should be weighed against its potential benefits.

Product Properties

Density: 0.79 g/cm3

Melting point: -98°C

Boiling point: 65°C

Flash point: 11°C

Vapour pressure @ 20°C: 129 hPa

Methanol Molecule

Further Information

MSDS:

Safety Data Sheet Methanol (ULSI) english

Sicherheitsdatenblatt Methanol (ULSI) german

Specs:

Specs Methanol (ULSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

MIBK - 2.50 l - VLSI - EVE/EUD!

TMIV1025

MIBK

Methyl Isobuthyl Ketone

General Information

MIBK is used in microelectronics as a developer for e-beam resists among other things.

Product Properties

Density: 0.80 g/cm3

Melting point: -80°C

Boiling point: 116°C

Flash point: 14°C

Vapour pressure @ 20°C: 19 hPa

MIBK Molecule

Further Information

MSDS:

Safety Data Sheet MIBK (VLSI) english

Sicherheitsdatenblatt MIBK (VLSI) german

Specs:

Specs MIBK (VLSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

n-Butylacetat - 5.00 l - VLSI

TNBAV1050

Butyl Acetate

C6H12O2

General Information

Butyl Acetate is a solvent with a boiling point of 127°C. The vapour pressure at room temperature is 10.7 hPa. Butyl Acetate has the chemical formula C6H12O2. It can be easily solved in nonpolar (organic) solvents, but fairly bad in water (4.3 g per Litre).

Product Properties

Density: 0.88 g/cm3

Melting point: -77°C

Boiling point: 127°C

Flash point: 27°C

Vapour pressure @ 20°C: 10.7 hPa

Further Information

MSDS:

Safety Data Sheet Butyl Acetate (VLSI) english

Sicherheitsdatenblatt Butyl Acetate (VLSI) german

Specs:

Specs Butyl Acetate (VLSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

PGMEA - 5.00 l - ULSI

MPGU1050

PGMEA

1-methoxy-2-propyl-acetate

General Information

PGMEA is the main solvent/thinner of almost all AZ® and TI photoresists due to its low vapour pressure and its suppression of particle formation in the (further diluted) resist. Additionally, PGMEA is often used for edge bead removal, since its low vapour pressure prevents further thinning of the coated resist film.

Product Properties

Density: 0.97 g/cm3

Melting point: -66°C

Boiling point: 125°C

Flash point: 45°C

Vapour pressure @ 20°C: 5 hPa

PGMEA Molecule

Further Information

MSDS:

Safety Data Sheet PGMEA (ULSI) english

Sicherheitsdatenblatt PGMEA (ULSI) german

Specs:

Specs PGMEA (ULSI)

Application Notes:

Solvents: Theory and Application english

Lösemittel: Theorie und Anwendung german

Further Information about Processing

TechniStrip Micro D350 - 2.50 l - ULSI

TD350U1025

Bottle size:

2.50 l

TechniStrip Micro D350

DMSO-based Stripper

General Information

TechniStrip® Micro D350 is a DMSO-based stripper and is a very well suited non-toxic substitute for the NMP that is regarded as toxic since a while. As a stripper or as lift off media, TechniStrip® Micro D350 can be regarded as a non toxic alternative to NMP. Mixtures with Cyclopentanone or with MEK even increase the strip performance of this product.

NOTE:

The solvent TechniStrip® Micro D350 has a melting point just below room temperature, so it can possi¬bly freeze in storage in cooler rooms. Thawing may require several days, but afterwards the product can still be used as it is.

For more details please download the info letter.

Further Information

MSDS:

Safety Data Sheet TechniStrip Micro D350 (ULSI) english

Sicherheitsdatenblatt TechniStrip Micro D350 (ULSI) german

TDS:

Technical Data Sheet TechniStrip Micro D350 (ULSI) english

Specs:

Specs TechniStrip Micro D350 (ULSI)

Application Notes:

Photoresist Removal english

Fotolack entfernen german

Further Information about Processing