DEVELOPER

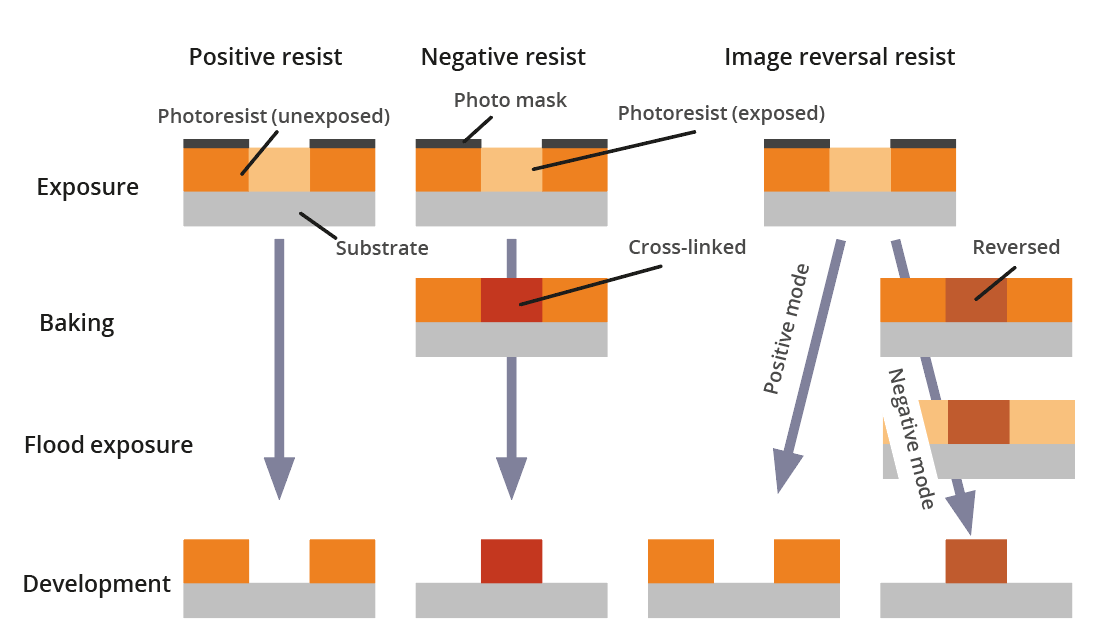

After exposure, the subsequent resist mask is present as a latent image in the photoresist: The exposed areas differ chemically from the unexposed areas. The task of the developer is to dissolve either the exposed (for positive resists) or unexposed (for negative resists) resist areas, whereby the finished resist structures are created from the latent image .

Selection criteria for developers

First of all, it must be clarified whether metal-ion-free ( MIF) must/should be developed with ready-to-use preparations or whether metal-ion-containing ( MIC) may be developed with concentrates to be diluted.

The

next selection criterion for a developer is compatibility

with the respective photoresist (see table below) or the

substrate material used.

The schematic process sequence of the exposure (above) up to the

developed resist features (below) in the processing of positive resists

(left column), negative resists (centre) and image reversal resists

(right); the latter in two possible modes. The special features of the

attainable resist profiles are not included in this scheme.

Further Information:

> Application areas and compatibilities

> Image Reversal Resist Processing

Filter

–

AZ 2026 MIF Developer - 5.00 l

1002026

AZ® 2026 MIF Developer

Metal Ion-free Developers

General Information

AZ® 2026 MIF is a TMAH-based developer for dip or puddle development, compatible with all AZ® photoresists from our portfolio.

Product Properties

The ready-to-use AZ® 2026 MIF developer is an aqueous 2.38% TMAH solution with a surfactant for uniform substrate wetting for puddle development, but is also suitable for immersion development. In addition, the AZ® 2026 MIF contains an additive to promote residue-free development with cross-linked resist structures. Since this additive slightly increases the dark erosion in positive resists, the AZ® 2026 MIF is less suitable for these resists, especially when high resolution requirements are required; in this case, the AZ® 326 MIF or AZ® 726 MIF would be the better choice. TMAH-based developers are always used when development has to be carried out metal ion free. In addition, TMAH-based developers are primarily recommended for our chemically amplified positive resists and our negative resists. For standard (non chemically amplified), DNQ-based positive resists without the requirement of metal ion-free development, a KOH or NaOH-based developer such as AZ® 400K or AZ® 351B can be considered instead of a TMAH-based developer for cost reasons. For very thin resist layers (< 1 µm) or very high resolution requirements, it can be useful to dilute AZ® 2026 MIF with water (AZ® 2026 MIF: water = 2:1 to a maximum of 1:1). AZ® 2026 MIF attacks aluminum with an etching rate of approx. 70 nm/min. If this cannot be tolerated, the Al-compatible "AZ® Developer " is an alternative, but this is based on sodium compounds and is therefore not metal ion-free.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® 2026 MIF Developer english

Safety Data Sheet AZ® 2026 MIF Developer german

TDS:

Technical Data Sheet AZ® 2026 MIF Developer english

Application Notes:

Further Information about development of photoreist english

Further Information about development of photoresist german

AZ 2033 MIF Developer - 5.00 l

1002033

AZ® 2033 MIF Developer

Metal Ion-free Developers

General Information

AZ® 300 MIF, AZ® 326 MIF, AZ® 726 MIF and AZ® 2026 MIF Developers are developer formulations with 2.38 % TMAH (tetramethylammoniumhydroxide) in H2O.

The AZ® 726 MIF Developer contains additionally a surfactant for better wetting and easy to settle up of puddle development. Additionally to the wetting agent of the AZ® 726 MIF the AZ® 2026 MIF contains a scum remover for complete and scum-free removal of resist layers on the price of a slightly higher dark erosion ratio.

However, for our negative resists, such as AZ® nLof 2000 series, AZ® 15nXT series, AZ® 125nXT resists this developer shows outstanding performance. Even for a positive resist like AZ® 10XT resist it significantly reduces t-topping if this problem occurs.

AZ® 2033 MIF is 3.00 % TMAH in H2O with surfactants added for fast and homogeneous substrate wetting and further additives for removal of resist residuals (residues in certain lacquer families), but at the cost of a higher dark removal. Compared to the AZ® 2026 MIF, the normality is not 0.26 but 0.33. Thus the development rate is higher with the AZ® 2033 MIF Developer.

Further Information

MSDS:

Safety Data Sheet AZ® 2033 MIF Developer english

Sicherheitsdatenblatt AZ® 2033 MIF Entwickler german

TDS:

Technical Data Sheet AZ® 2033 MIF Developer english

Application Notes:

Development of Photoresist english

Entwicklung von Fotolack german

AZ 300 MIF Developer - 5.00 l

1000300

AZ® 300 MIF Developer

Metal Ion-free Developers

General Information

AZ® 300 MIF, AZ® 326 MIF, AZ® 726 MIF and AZ® 2026 MIF Developers are developer formulations with 2.38 % TMAH (tetramethylammoniumhydroxide) in H2O.

The AZ® 726 MIF Developer contains additionally a surfactant for better wetting and easy to settle up of puddle development. Additionally to the wetting agent of the AZ® 726 MIF the AZ® 2026 MIF contains a scum remover for complete and scum-free removal of resist layers on the price of a slightly higher dark erosion ratio.

However, for our negative resists, such as AZ® nLof 2000 series, AZ® 15nXT series, AZ® 125nXT resists this developer shows outstanding performance. Even for a positive resist like AZ® 10XT resist it significantly reduces t-topping if this problem occurs.

AZ® 2033 MIF is 3.00 % TMAH in H2O with surfactants added for fast and homogeneous substrate wetting and further additives for removal of resist residuals (residues in certain lacquer families), but at the cost of a higher dark removal. Compared to the AZ® 2026 MIF, the normality is not 0.26 but 0.33. Thus the development rate is higher with the AZ® 2033 MIF Developer.

Further Information

MSDS:

Safety Data Sheet AZ® 300 MIF Developer english

Sicherheitsdatenblatt AZ® 300 MIF Entwickler german

TDS:

Technical Data Sheet AZ® 300 MIF Developer english

Application Notes:

Development of Photoresist english

Entwicklung von Fotolack german

AZ 303 Developer - 5.00 l

1000303

AZ® 303 Developer

Inorganic, Metal Ion Containing Developer

General Information

AZ® 303 MIC is a KOH and NaOH based developer for positive and negative resists.

Product Features

AZ® 303 Developer is based on an aqueous KOH and NaOH solution and contains strong surfactants. It is compatible with positive and negative resists and is therefore suitable, for example, as the only non-TMAH-based developer for the AZ® nLOF 2000 series. AZ® 303 Developer is usually used diluted 1: 5 - 1:10 with water.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® 303 Developer english

Safety Data Sheet AZ ® 303 Entwickler german

TDS:

Technical Data Sheet AZ® 303 Developer english

Application Notes:

Development of Photoresist english

Development of Photoresist german

AZ 326 MIF Developer - 5.00 l

1000326

AZ® 326 MIF Developer

Metal Ion-free Developer

General Information

AZ® 326 MIF is a TMAH-based developer for dip or spray development, compatible with all AZ®</sup photoresists from our portfolio.

Product Features

The ready-to-use AZ® 326 MIF developer is an aqueous 2.38% TMAH solution without any additives. This makes it suitable for dip or spray development, but less for puddle development, for which the AZ® 726 MIF developer is the better choice due to its special surfactant for substrate wetting. TMAH-based developers are always used when development must be carried out metal ion free. In addition, TMAH- based developers are primarily recommended for our chemically amplified positive resists and our negative resists. For very thin resist layers (< 1 µm) or very high resolution requirements, it can be useful to dilute the AZ® 326 MIF with water (AZ® 326 MIF : water = 2:1 to a maximum of 1:1). AZ® 326 MIF attacks aluminum with an etching rate of approx. 70 nm/min. If this cannot be tolerated, the Al-compatible AZ® Developer is an alternative, which, however, is based on sodium compounds and is therefore not metal ion-free.

For standard (non chemically amplified), DNQ-based positive resists without the requirement of metal ion-free development, a KOH- or NaOH-based developer such as AZ® 400K or AZ® 351B can be considered instead of a TMAH-based developer for cost reasons. For cross-linking negative resists, AZ® 2026 MIF can prove advantageous, which promotes residue-free development with these resists through certain additives.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® 326 MIF Developer english

Safety Data Sheet AZ® 326 MIF Entwickler german

TDS:

Technical Data Sheet AZ® 326 MIF Developer english

Application Notes:

Development of Photoresist english

Development of Photoresist german

AZ 340 Developer - 5.00 l

1000340

AZ® 340 Developer

Inorganic Developers

General Information

AZ® 340 Developer is a high normality sodium based developer concentrate for use in on-site custom dilution applications. This developer concentrate is buffered for extended bath life and stable develop rates in batch processes. Dilute using 1 part AZ® 340 Developer to 4 parts DI water for high contrast processing. Developer normality (and develop rate) may be increased as required by increasing the AZ® 340 Developer to water ratio.

Further Information

MSDS:

Safety Data Sheet AZ® 340 Developer english

Sicherheitsdatenblatt AZ® 340 Developer german

TDS:

Technical Data Sheet AZ® 340 Developer english

Application Notes:

Development of Photoresist english

Entwicklung von Fotolack german

AZ 351 B Developer - 5.00 l

1000351

AZ® 351B Developer

Inorganic, Metal Ion Containing Developer

General Information

AZ® 351B Developer is a boric acid buffered, NaOH-based developer for non-chemically amplified positive resists.

Product Features

AZ® 351B Developer is a NaOH-based developer, particularly suitable for developing non-chemically amplified positive resists with layer thicknesses of a few µm. AZ® 351B Developer comes as a concentrate and is usually diluted 1: 4 with water. To increase selectivity, a 1: 5 - 1:6 dilution can also be applied, but this significantly reduces the development rate and is therefore not a reasonable option for thicker resist films. If the requirements for steep resist sidewalls are low, the AZ® 351B can also be set stronger (1:3.5 - 1:3) if higher development rates are required , but this leads to a disproportionate increase in dark erosion. AZ® 351B is less suitable for negative resists or chemically amplified positive resists; TMAH-based developers such as the AZ® 326 MIF, AZ® 726 MIF or AZ® 2026 MIF are recommended here. AZ® 351B attacks aluminum with an etching rate of - depending on the concentration of the developer dilution - several 10 nm/min to over 100 nm/min. If this cannot be tolerated, the Al-compatible AZ® Developer can be an alternative.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® 351B Developer english

Safety Data Sheet AZ® 351B Entwickler german

TDS:

Technical Data Sheet AZ® 351B Developer english

Application Notes:

Development of Photoresist english

Development of Photoresist german

AZ 400 K Dev 1:4 - 5.00 l

1004145

AZ® 400K Developer 1:4

Inorganic, Metal Ion Containing Developer

General Information

AZ® 400K Developer 1:4 is a boric acid buffered, KOH-based ready-to-use developer for non-chemically amplified positive resists.

Product Features

AZ® 400K Developer 1:4 is an AZ® 400K that has already been pre-diluted for use. As a KOH-based developer, this developer is particularly suitable for developing thicker, non-chemically amplified positive resists, but can also be used for thinner resist layers if the resolution requirements are not too high. AZ® 400K Developer is less suitable for negative resists or chemically amplified positive resists; TMAH-based developers such as the AZ® 326 MIF, AZ® 726 MIF or AZ® 2026 MIF are recommended here. AZ® 400K Developer attacks aluminum with an etching rate of - depending on the concentration of the developer dilution - several 10 nm/min to over 100 nm/min. If this cannot be tolerated, the Al-compatible AZ® Developer can be an alternative.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® 400K 1:4 Developer english

Safety Data Sheet AZ® 400K 1:4 Developer german

TDS:

Technical Data Sheet AZ® 400K 1:4 Developer english

Information AZ® 400K 1:4 Developer english

Application Notes:

Development of Photoresist english

Development of Photoresist german

AZ 400 K Developer - 5.00 l

1000400

AZ® 400K Developer

Inorganic, Metal Ion Containing Developer

General Information

AZ® 400K Developer is a boric acid buffered, KOH-based developer for non-chemically amplified positive resists.

Product Features

As a KOH-based developer, AZ® 400K is particularly suitable for developing thicker, non-chemically amplified positive resists, but can also be used for thinner resist layers if the resolution requirements are not too high. AZ® 400K comes as a concentrate and is usually diluted 1: 4 with water. To increase selectivity, a 1: 5 - 1:6 dilution can also be selected, but this significantly reduces the development rate and is therefore not a reasonable option for thick resist processing. For very thick resist films and/or very steep resist sidewalls are not required, AZ® 400K can also be used at a stronger dilution (1:3.5 - 1:3), which increases the development rate but significantly increases the dark removal. AZ® 400K is less suitable for negative resists or chemically amplified positive resists; TMAH-based developers such as the AZ® 326 MIF, AZ® 726 MIF or AZ® 2026 MIF are recommended here. AZ® 400K attacks aluminum with an etching rate of - depending on the concentration of the developer dilution - several 10 nm/min to over 100 nm/min. If this cannot be tolerated, the Al-compatible AZ® Developer can be an alternative.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® 400K Developer english

Safety Data Sheet AZ® 400K Developer german

TDS:

Technical Data Sheet AZ® 400K Developer english

Information AZ® 400K Developer english

Application Notes:

Development of Photoresist english

Development of Photoresist german

AZ 726 MIF Developer - 5.00 l

1000726

AZ® 726 MIF Developer

Metal Ion-free Developers

General Information

AZ® 726 MIF is a TMAH-based developer for dip or puddle development, compatible with all AZ® photoresists from our portfolio.

Product Features

The ready-to-use AZ® 726 MIF Developer is an aqueous 2.38% TMAH solution with a surfactant for even substrate wetting for puddle development, but is also suitable for immersion development. For spray development, the surfactant-free AZ® 326 MIF would be the better choice to avoid foaming. TMAH-based developers are always used when metal ion-free development is required. In addition, TMAH-based developers are primarily recommended for our chemically amplified positive resists and our negative resists. For standard (non chemically amplified), DNQ-based positive resists without the requirement for metal ion-free development, a KOH or NaOH-based developer such as AZ® 400K or AZ® 351B can be considered instead of a TMAH-based developer for cost reasons. For cross-linking negative resists, the AZ® 2026 MIF can prove to be advantageous, as it promotes residue-free development with these resists thanks to certain additives. For very thin resist layers (< 1 µm) or very high resolution requirements, it can be useful to dilute the AZ® 726 MIF Developer with water (AZ® 726 MIF: water = 2:1 to a maximum of 1:1). AZ® 726 MIF attacks aluminum with an etching rate of approx. 70 nm/min. If this cannot be tolerated, the Al-compatible AZ® Developer is an alternative, but this is based on sodium compounds and is therefore not free of metal ions.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® 726 MIF Developer english

Safety Data Sheet AZ® 726 MIF Entwickler german

TDS:

Technical Data Sheet AZ® 726 MIF Developer english

Application Notes:

Development of Photoresist english

Development of Photoresist german

AZ Developer - 5.00 l

1000001

AZ® Developer

Inorganic, Metal Ion Containing Developer

General Information

AZ® Developer is a sodium salt-based, aluminum-compatible developer for non-chemically amplified positive resists.

Product Features

AZ® Developer is based on an aqueous Sodium metasilicate/Sodium phosphate solution. In contrast to NaOH, KOH or TMAH-based developers, this developer does not show any significant aluminum attack and is suitable for the development of non-chemically amplified positive resists. For thicker resist layers or when the requirements for resolution and steepness of the resist sidewalls are not too high, the AZ® Developer can be used undiluted. For thin resists and higher resolution requirements, it can be diluted 1:1 with water. An AZ® Developer: Water = 2:1 dilution represents a good compromise for many applications. For negative resists or chemically amplified positive resists, the AZ® Developer usually does not show satisfactory results. TMAH-based developers are recommended for these, but these are not aluminum compatible.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® Developer english

Safety Data Sheet AZ® Developer german

TDS:

Technical Data Sheet AZ® Developer english

Application Notes:

Development of Photoresist english

Development of Photoresist german

AZ Developer 1:1 - 5.00 l

1000115

AZ® Developer 1:1

Inorganic Developers

General Information

AZ® Developer 1:1 is a ready-to-use product and is a 1:1 dilution of AZ Developer. The developer is optimized for minimum Al attack. It is an odourless, aqueous, inorganic, alkaline solution, which is compatible with batch and in-line developing processes. AZ® Developer 1:1 is for high contrast. The dark erosion of AZ® Developer 1:1 is slightly higher as compared to other developers. AZ® Developer 1:1 can be used in combination with most families of AZ® Photoresists (i.e. AZ® 1500, AZ® ECI3000 and AZ® 4500 or AZ® PL177). AZ® Developer 1:1 displays the lowest aluminium etch rate (it is more or less zero!) of all AZ® Developer 1:1 types and is ideal for metal levels.

Further Information

MSDS:

Safety Data Sheet AZ® Developer 1:1 english

Sicherheitsdatenblatt AZ® Developer 1:1 german

TDS:

Technical Data Sheet AZ® Developer 1:1 english

Application Notes:

Development of Photoresist english

Entwicklung von Fotolack german