AZ NLOF 2020 Photoresist - 3.785 l

Product information "AZ NLOF 2020 Photoresist - 3.785 l"

AZ® nLOF 2020

Thick Negative Resist for Lift Off

General Information

The i-line sensitive negative resist AZ® nLOF 2020 is, with a resist film thickness of approx. 2 µm, the thinnest member of the AZ® nLOF 2000 series, which is primarily optimized for lift-off applications.

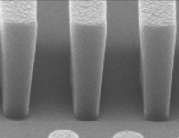

700 nm resist lines attained with the 2.0 µm thick AZ® nLOF 2020.

Product Properties

AZ® nLOF 2020 covers a resist film thickness range of - depending on the spin speed - approx. 1.5 - 2.5 µm. It is only i-line sensitive and requires a post exposure bake after exposure to complete the cross-linking induced during exposure. The developed resist structures are (slightly) negative, as desired for lift-off applications, because the upper resist areas receive a slightly higher dose during exposure and thus cross-link more strongly than the resist areas close to the substrate. This undercut can only be increased to a limited extent using a lower exposure dose, because the low resist film thickness is in the range of the penetration depth of the exposure wavelength, meaning that even with low exposure doses it is always exposed through to the substrate. If even thinner resist layers are desired, the AZ® nLOF 2020 can be diluted with PGMEA = AZ® EBR Solvent or the use of AZ® LNR-003 can be considered. For thicker layers, we recommend the AZ® nLOF 2035 (approx. 3 - 4 µm) or the even thicker AZ® nLOF 2070 (> 5 µm), both of which differ from the AZ® nLOF 2020 only in the solvent content.

Developers

TMAH-based developers such as the ready-to-use AZ® 326 MIF (immersion development), AZ® 726 MIF (puddle development) or AZ® 2026 MIF (which uses an additive to promote residue-free development, especially with cross-linking resists) are recommended for developing the AZ® nLOF 2020. KOH- or NaOH-based developers such as the AZ® 400K or AZ® 351Bare generally not suitable for the AZ® nLOF 2020. If TMAH-based developers cannot be used, an attempt with a KOH-based developer in higher concentration than usual can be considered.

Removers

If the resist structures have not been thermally cross-linked too much, for example through metallization, stripping or lift-off with organic solvents (acetone rinsed with isopropanol or DMSO) can be successful. For more strongly cross-linked resist structures, high-performance strippers such as the NMP-free TechniStrip NI555 or AZ® 920 Remover are recommended, or in the case of alkaline-sensitive substrate materials (such as aluminum), the TechniStrip MLO 07.

Thinning/ Edge Bead Removal

If the resist is to be diluted for spin coating, PGMEA = AZ® EBR Solvent is an option. PGMEA is the solvent for AZ® nLOF 2020 anyway and is also recommended for edge wall removal if necessary.

Further Information

Our safety data sheets and some of our technical data sheets are password-protected.

You will receive the access data after completing the form.

The access data for the data sheets are not your login data from our shop!

MSDS:

Safety Data Sheet AZ® nLOF2020 Photoresist english

Safety Data Sheet AZ® nLOF2020 Photoresist german

TDS:

Technical Data Sheet AZ® nLOF2000 Series english

Information AZ® nLOF2000 Series english

Information AZ® nLOF2000 Series german

Application Notes:

Further Information about Photoresist Processing

Related products

Developer

Remover