AZ MIR 701 Photoresist (11 CPS) - 3.785 l

Product information "AZ MIR 701 Photoresist (11 CPS) - 3.785 l"

AZ® MIR 701 (11CPS)

High Resolution and Temperature Stability

General Information

AZ® 701 MIR Series for 0.7 – 3.0 µm Resist Film Thickness (g-, h- and I-line) As thermally stable (softening point > 130°C), high-resolution positive resist, the AZ® 701 MIR (11CPS) is optimised especially for dry chemical etching of fine to very fine structures. This resist can be easily further diluted in order to attain even better resolutions, for example in applications of laser-interference lithography. We sell this resist in two different viscosities of 11CPS, 14CPS and 29CPS. It can be used with common NaOH, KOH or TMAH based developers.

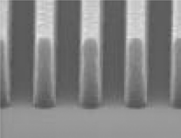

300 nm resist lines attained with the AZ® 701 MIR

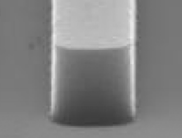

1.2µm structure after 130°C hardbake

Product Properties

- Very high resolution, for 0.5 µm and 0.35 µm technology nodes

- High thermal stability

- Excellent process latitude for both line/space and contact whole applications

- Steep resist-sidewalls and high aspect ratio for dry etching or ion implantation

- Broad process parameter window for stable and reproducible litho-processes

- Compatible with all common strippers (e.g. with AZ® 100 Remover, organic solvents or aqueous alkaline)

- g-, h- and i-line sensitive (approx. 320 - 440 nm)

- Resist film thickness range AZ® MIR 701 (11CPS): approx. 0.6 – 1.0 µm

Developers

If metal ion containing developers can be used, the NaOH-based AZ® 351B in a 1:4 dilution (for resist film thicknesses and resolutions < 1 µm 1:5 - 1:6 dilution recommended) is a suited developer. The KOH-based AZ® 400K (also 1:4 - 1:6 diluted) is possible, but due to its lower selectivity not recommended, if a high resolution or steep resist sidewalls are required. If metal ion free developers have to be used, we recommend the TMAH-based AZ® 326 MIF or AZ® 726 MIF developer, either undiluted, or - for maximum resolution and very thin resist layers - moderately 3:1 - 2:1 (3 parts Developer:1 part of DI-Water) diluted with water.

Removers

For non cross-linked resist films the AZ® 100 Remover, DMSO or other common organic solvents can be used as stripper. If the resist film is cross-linked (e.g. by high temperature steps > 140°C, during plasma processes such as dry etching or during ion implantation), we recommend the NMP-free TechniStrip P1316 or AZ® Remover 920.

Thinning/ Edge Bead Removal

We recommend for thinning and edge bead removal the AZ® EBR Solvent or PGMEA. AZ® EBR Solvent 70/30 is possible as well for edge bead removal.

Further Information

MSDS:

Safety Data Sheet AZ® MIR 701 (11CPS) Photoresist english

Sicherheitsdatenblatt AZ® MIR 701 (11CPS) Fotolack german

TDS:

Technical Data Sheet AZ® MIR 701 Series english

Application Notes:

Further Information about Photoresist Processing

Related products

Developer

Remover