Adhesion Promoter

Filter

–

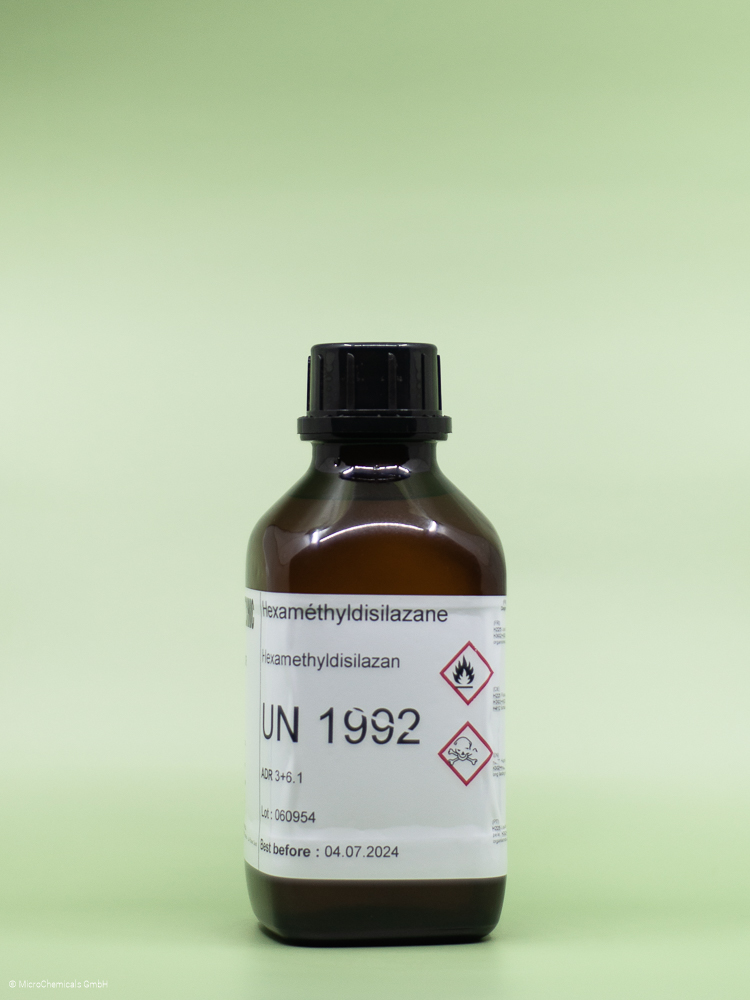

Hexamethyldisilazan - HMDS - 1.00 l - VLSI - EUD/EVE!

THMV1010

HMDS

Adhesion Promotion

General Information

HMDS (HexaMethylDiSilazane) is a metal-ion-free adhesion promoter between the substrate and the photoresist, which is applied from the gas phase to heated substrates and thereby chemically bonds to the substrate surface.

How HMDS Works

On water-free surfaces, HMDS chemically bonds its Si atom to the oxygen of oxidized surfaces, accompanied by the release of ammonia (NH3). The methyl groups of the HMDS fragment thereby form a hydrophobic surface and thus improve resist wetting and adhesion.

How To Apply HMDS

The correct application of HMDS is very important in order not to further deteriorate the resist adhesion:

In a so-called bubbler, water free nitrogen saturates at room temperature with HMDS vapour. The N2 + HMDS streams onto the heated (75 - 120°C), water free substrate thereby forming a thin layer of chemically bonded Si (CH3)3 groups responsible for the desired hydrophobic characteristics.

How Not To Apply HMDS

In the case of spin-coating the HMDS, a thick (= more than a monolayer) HMDS film forms on the surface without displacing water and without chemically bonding.

After resist coating during the softbake, this excess of HMDS releases ammonia which diffuses into the resist and crosslinks the resin near the substrate. As a consequence, through-development sometimes becomes impossible.

For the same reason, NEVER apply HMDS in a spin coater. HMDS vapour will diffuse into all resist films subsequently coated, and partially crosslink the resist film during softbake, which lowers the development rate and can deteriorate the resist profile and attainable resolution.

Further Information

MSDS:

Safety Data Sheet HMDS (VLSI) english

Sicherheitsdatenblatt HMDS (VLSI) german

Specs:

Specs HMDS (VLSI)

Application Notes:

Substrate Cleaning and Adhesion english

Substrat Reinigung und Haftung german

Further Information about Processing

TI Prime - 1.00 l

100p001

Bottle size:

1.00 l

TI Prime

Adhesion Promotion

General Information

The TI Prime adhesion promoter improves resist adhesion on substrates such as Si or glass. TI Prime contains Titanium, for this reason TI Prime should not be used where a contamination with Titanium could be a problem.

In contrast to HMDS, TI Prime is applied via spin coating, where a sub-mono layer is adsorbed onto the surface. In a subsequent baking step the surface is activated. After cooling down the fusion should be applied.

Further Information

MSDS:

Safety Data Sheet TI Prime english

Sicherheitsdatenblatt TI Prime german

TDS:

Technical Data Sheet TI Prime english

Application Notes:

Substrate Cleaning and Adhesion english

Substrat Reinigung und Haftung german

Further Information about Processing